Product Overview

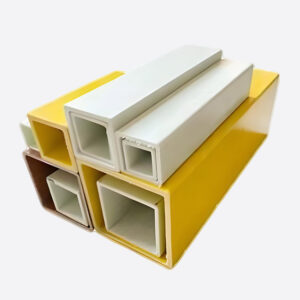

FRP Rectangular Tubes are manufactured using the pultrusion process, combining fiberglass reinforcements with high-quality resins. This results in strong, non-conductive, and corrosion-resistant structural profiles suitable for indoor and outdoor environments.

Key features include:

Superior strength-to-weight ratio

Resistance to chemicals, moisture, and UV rays

Non-magnetic and electrically non-conductive

Easy fabrication and installation

Detailed Specifications

Standard Dimensions & Tolerances

Width: 20 mm – 200 mm

Height: 10 mm – 150 mm

Wall Thickness: 3 mm – 12 mm

Length: Standard 6 m or customized upon request

Material & Mechanical Properties

Resin System: Polyester, Vinyl Ester, Epoxy (optional)

Fiber Reinforcement: Continuous E-glass roving & mat

Density: 1.8–2.0 g/cm³

Tensile Strength: ≥ 350 MPa

Flexural Strength: ≥ 450 MPa

Thermal Conductivity: Low, ideal for insulation

Service Temperature: -40°C to +120°C

Product Data & Technical Documents

Download datasheets, chemical resistance charts, test reports and cutting templates.

Applications of FRP Rectangular Tubes

FRP Rectangular Tubes are widely used across industries due to their versatility and durability:

Construction & Infrastructure – support beams, roofing frames, pedestrian bridges

Electrical & Utilities – cable trays, ladder rungs, transformer enclosures

Marine & Offshore – handrails, platforms, structural reinforcements in corrosive environments

Transportation – lightweight framing for vehicles, trailers, and railway components

Chemical Plants – structures exposed to acids, alkalis, and harsh weather

Advantages of FRP Rectangular Tubes

Corrosion Resistance: Withstand chemicals, saltwater, and weathering

Lightweight but Strong: Easy handling with excellent load-bearing performance

Electrical & Thermal Insulation: Safe for electrical and high-temperature environments

Low Maintenance: Long service life with minimal upkeep costs

Design Flexibility: Easy to cut, drill, and assemble with standard tools

Cost-Effective: Reduced lifecycle costs compared to steel or aluminum

Why Choose Us as Your FRP Rectangular Tube Supplier?

In-house pultrusion production with strict quality control

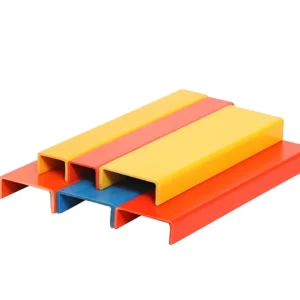

Custom dimensions, colors, and resin formulations available

Export experience to North America, Europe, Middle East, and Asia

Fast delivery and bulk supply capability for industrial projects

Competitive pricing for OEM & B2B partnerships

Frequently Asked Questions (FAQ)

Q1: What is the difference between FRP Rectangular Tubes and steel tubes?

A: FRP Rectangular Tubes are lightweight, corrosion-resistant, and electrically non-conductive, making them safer and longer-lasting in harsh environments compared to steel.

Q2: Can I order custom sizes or resin systems?

A: Yes, we provide tailored solutions including size, wall thickness, resin type (polyester, vinyl ester, epoxy), and surface finishing.

Q3: Are FRP Rectangular Tubes suitable for outdoor use?

A: Absolutely. They offer UV resistance and weather durability, making them ideal for outdoor structures and marine environments.

Q4: How do I cut or install fiberglass tubes?

A: FRP Rectangular Tubes can be cut and drilled using standard carbide-tipped tools. Installation is straightforward and requires no special equipment.

Q5: What industries use FRP Rectangular Tubes the most?

A: Construction, electrical utilities, marine, chemical processing, and transportation industries are the main users.