Hey, pal, are you still waiting for Black Friday? The discounts we have now are like never before! Our quality is top-notch! Reach out to us right this minute and you’ll get offers you can’t even imagine!

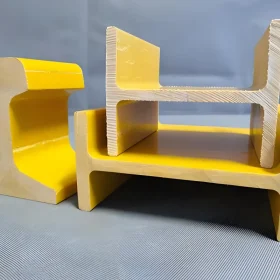

FRP I Beam

Why FRP I Beams?

Tired of steel beams rusting in corrosive environments? Struggling with heavy materials that drive up transport costs? Say hello to FRP I Beams (Fiberglass H Beams)—the lightweight, high-strength alternative revolutionizing industries worldwide!

Key Features

✅ Unmatched Corrosion Resistance

Perfect for harsh environments (chemical plants, marine applications, wastewater treatment) where steel fails. No more rust, no more replacements!

✅ Lightweight & Easy to Install

Weighing 70% less than steel, FRP I Beams reduce labor costs and accelerate project timelines. Imagine cutting installation time by half!

✅ High Strength-to-Weight Ratio

Engineered to handle heavy loads without bending or cracking. Safety and durability? We’ve got you covered.

✅ Low Maintenance & Long Lifespan

Forget annual repainting or coatings. FRP beams last 30+ years with minimal upkeep. Save money, save time, save effort.

✅ Non-Conductive & Fire-Retardant Options

Ideal for electrical substations, oil & gas facilities, and fire-sensitive zones. Safety first, always.

Applications

Where can FRP I Beams transform your projects?

- Industrial Platforms & Walkways (chemical plants, mining, power generation)

- Bridges & Boardwalks (coastal areas, high-moisture zones)

- Support Structures for tanks, pipes, and equipment

- Marine & Offshore Installations (docks, boat ramps, seawalls)

- Architectural Designs requiring sleek, rust-free aesthetics

Is your project exposed to saltwater, chemicals, or extreme weather? FRP I Beams are your answer.

Why Global Clients Choose Us?

🌍 Customization Ready

Need specific dimensions, colors, or load capacities? We tailor beams to your exact requirements.

🌍 Competitive Pricing & Fast Lead Times

No hidden costs. Get factory-direct pricing and shipments within 2-3 weeks.

🌍 Certified Quality

Our beams meet ISO, ASTM, and CE standards, ensuring reliability you can trust.

🌍 24/7 Technical Support

From design to installation, our experts are here to help. Your success is our priority.

Ready to Upgrade Your Projects?

📩 Contact us today for a FREE sample or a customized quote!

📞 WhatsApp: +8613833857335

📧 Email: info@fiberglass-profiles.com

Still unsure?

👉 Ask us about our case studies! See how fiberglass H beams saved 50% costs for a wastewater plant in Germany.

FRP profiles, fiberglass grating

FRP profiles, fiberglass grating

If our website has no specs you need, please contact online customer service or leave us a message. Our professional sales personnel will reply to you the first time!

If our website has no specs you need, please contact online customer service or leave us a message. Our professional sales personnel will reply to you the first time! Packing: in pallet

Packing: in pallet

Scan the QR Code with WeChat