Detailed Product Description

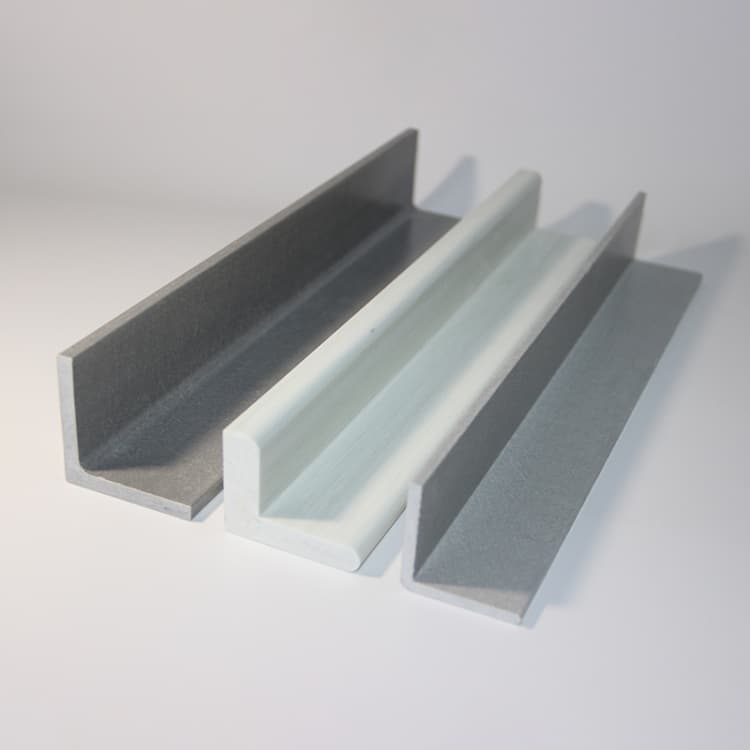

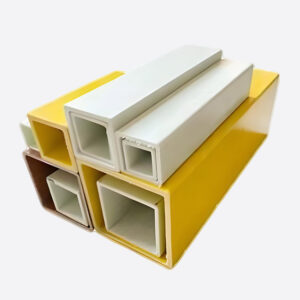

FRP Angle Bars are manufactured using the pultrusion process, which ensures consistent quality and dimensional accuracy. They combine the strength of fiberglass with the durability of thermosetting resin, resulting in profiles that withstand harsh environments such as chemical exposure, moisture, and extreme temperatures.

Unlike steel, FRP angles will not rust, warp, or corrode, making them a long-lasting solution for demanding structural applications. With excellent load-bearing capacity and ease of installation, fiberglass angles are commonly used in walkways, platforms, frames, and support structures.

Product Data & Technical Documents

Download datasheets, chemical resistance charts, test reports and cutting templates.

Technical Specifications

General Properties

Material: Fiberglass reinforced polymer (FRP / GRP)

Resin Options: Polyester, Vinyl Ester, Epoxy

Shape: Equal Angle, Unequal Angle

Surface: Smooth, Gritted, or Customized

Mechanical & Physical Properties

Tensile Strength: 200 – 350 MPa

Flexural Strength: 150 – 300 MPa

Density: 1.8 – 2.0 g/cm³

Electrical Insulation: Non-conductive

Corrosion Resistance: Excellent against acids, alkalis, and saltwater

Standard Sizes (Example)

Equal Angle: 25×25 mm up to 100×100 mm

Thickness: 3 mm – 10 mm

Length: Standard 6 m (customized available)

Applications of FRP Angle Bars

Construction and Infrastructure

Support frames, handrails, staircases, and platforms

Structural reinforcement in buildings and bridges

Industrial and Chemical Plants

Corrosion-resistant supports for pipelines and tanks

Equipment frames in chemical processing facilities

Marine and Offshore

Ship structures, docks, and walkways

Saltwater-resistant framing components

Electrical and Utility

Non-conductive support structures for electrical equipment

Utility pole crossarms and cable trays

Key Advantages of FRP Angle Bars

Corrosion Resistant – Performs well in acidic, alkaline, and saltwater environments

Lightweight yet Strong – Easy to transport and install without heavy machinery

Non-Conductive – Provides electrical and thermal insulation for safety

Maintenance-Free – No need for painting or anti-rust treatment

Long Service Life – Durable and cost-effective compared to steel or aluminum

Customizable – Available in various resin types, sizes, and surface finishes

FAQ – Frequently Asked Questions

Q1: What is the difference between FRP Angle Bar and steel angle?

A: FRP Angle Bars are much lighter, corrosion-resistant, and non-conductive, whereas steel angles are heavier, conductive, and prone to rust.

Q2: Can FRP Angles replace steel in structural applications?

A: Yes, in many cases FRP Angles are used as a direct replacement for steel, especially where corrosion resistance and lightweight properties are required.

Q3: Are FRP Angle Bars suitable for outdoor use?

A: Absolutely. Their UV and weather resistance make them ideal for outdoor construction, marine, and utility applications.

Q4: What surface options are available?

A: FRP Angles can be produced with smooth or gritted surfaces for enhanced slip resistance, depending on the application.

Q5: Can sizes and thickness be customized?

A: Yes. We offer tailored dimensions, thicknesses, and colors to meet project-specific requirements.