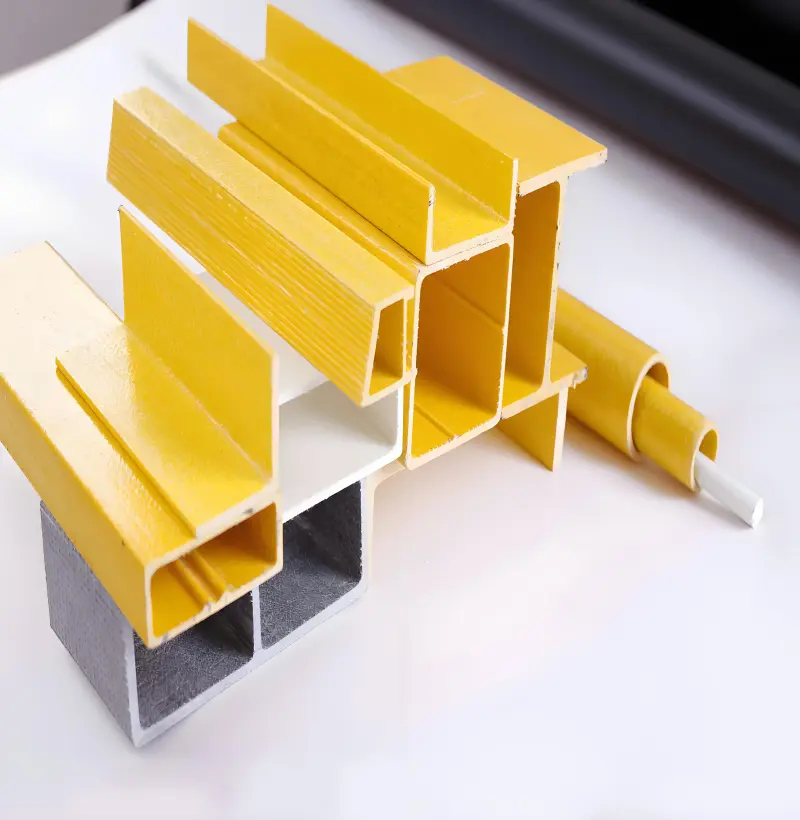

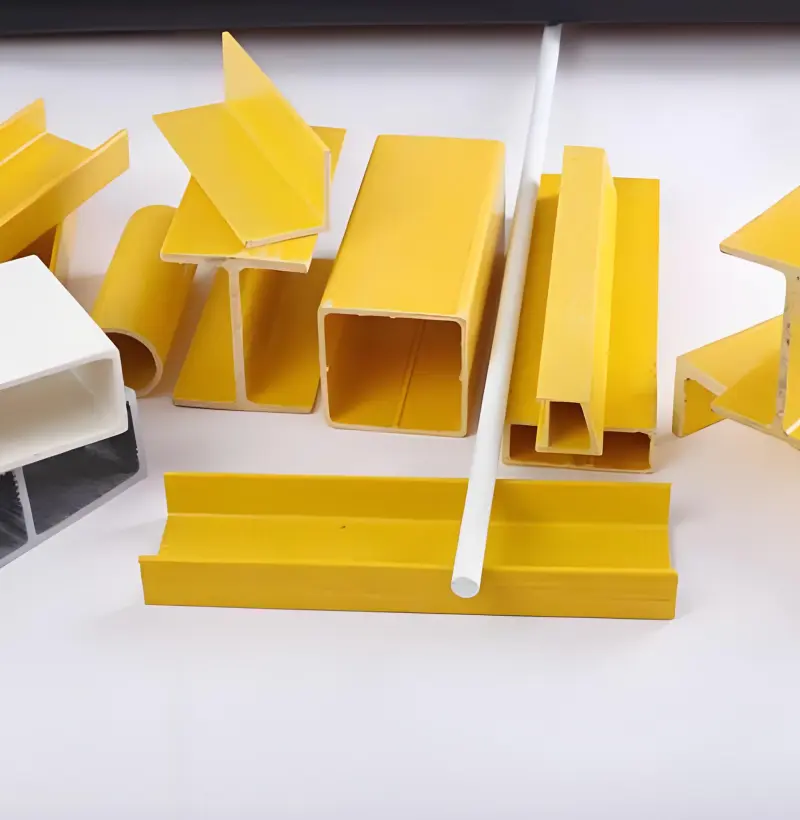

Product Overview

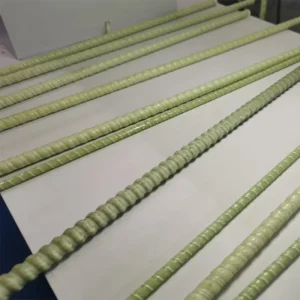

Pultruded FRP square tubes are produced by pulling continuous glass fibers and mats through a resin bath and a heated die. The result is a dimensionally accurate, fiber-reinforced thermoset profile optimized for bending, axial loads and long-term environmental exposure. Typical finishes include smooth, gel-coat or UV-stabilized options for outdoor use.

Product Data & Technical Documents

Download datasheets, chemical resistance charts, test reports and cutting templates.

Key Features & Selling Points

High corrosion resistance — resists rust, acids, alkalis and most industrial chemicals (ideal for marine or chemical plants).

Excellent strength-to-weight ratio — much lighter than steel for easier handling and lower shipping cost.

Non-conductive & RF-transparent — suitable for telecommunications and electrical insulation applications.

Low maintenance — no painting, no rust treatment; long service life in harsh environments.

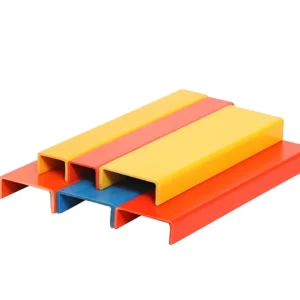

Customizable — sizes, wall thicknesses, resin systems (polyester/epoxy/vinyl-ester) and colors available.

Technical Specifications (typical / standard pultruded ranges)

Note: composite properties depend on resin system and fiber architecture. Below are typical / commonly stocked ranges used in pultruded structural FRP square tubes product lines. Always request the manufacturer’s data sheet for project-level design values and allow material/lot testing for critical projects.

Material & standards

Manufacturing: Pultrusion process (continuous fiber + thermoset resin).

Typical resin systems: Polyester (standard grade), vinyl-ester (higher chemical/heat resistance), epoxy (high performance).

Test standards referenced: ASTM D638 (tensile), ASTM D790 (flexural), ASTM D695 (compressive) — check supplier datasheets.

Typical mechanical property ranges (reference / design guide values)

Tensile strength (ultimate): manufacturer grades vary; pultruded structural grades commonly report on the order of tens to a few hundreds MPa depending on formulation — consult supplier D-sheet for exact values.

Tensile modulus (longitudinal): typical pultruded profiles: ~12–18 GPa (approx. 1.8–2.6×10^4 MPa reported in common datasheets as longitudinal modulus ranges).

Compressive / flexural strength: commonly in the same order of magnitude as tensile/flexural values per ASTM D790/D695; see supplier sheet for exact numbers.

Specific gravity / density: ~1.7–2.0 g/cm³ (FRP is ~70–80% lighter than steel by weight per same volume).

Standard finish & lengths

Stock finishes: gel-coat, smooth, or factory painted; UV-stabilized gel-coat for outdoor exposure.

Stock lengths: typical stocked lengths include 8 ft (96″), 10 ft, 20 ft (240″) depending on supplier — custom cut lengths available.

Common Sizes & Typical Stock Offerings

| Outer size (in) | Wall thickness (in) | Typical length options |

|---|---|---|

| 1¼” × 1¼” | 1/8″ (3.2 mm) / 1/4″ (6.35 mm) | 8 ft, 20 ft (stock varies by supplier). |

| 1½” × 1½” | 1/8″ / 1/4″ | 8 ft, 20 ft. |

| 2″ × 2″ | 1/8″ / 1/4″ | 8 ft, 20 ft. |

| 3″ × 3″ | 1/4″ | 8 ft, 20 ft. |

| 4″ × 4″ | 1/4″ | 8 ft, 20 ft. |

Suppliers often list additional fractional sizes and special wall thicknesses; large projects typically require a supplier cut-to-length service.

Applications (where buyers have purchase intent)

Industrial platforms, walkways & handrails — corrosion-resistant railings and supports in chemical plants.

Marine structures — docks, pilings, ladders, and structural framing exposed to saltwater.

Electrical & telecom — non-conductive supports, antenna mounts and RF-transparent housings.

Architectural & building facades — lightweight, decorative structural elements and canopies.

Custom machinery frames & fixtures — where corrosion, weight and non-magnetic properties matter.

Advantages (why buy FRP square tubes vs alternatives)

Longevity in corrosive environments — significantly better than carbon steel in salt, chemical and biological exposures.

Lower installed cost for hostile environments — reduced maintenance, no cathodic protection, no periodic painting.

Lightweight — easier handling and lower support/transport costs vs steel.

Non-magnetic / non-conductive — key for certain electrical or sensing applications.

Comparison: Fiberglass Square Tubes vs Steel / Aluminum / Wood

| Property | FRP (fiberglass square tube) | Carbon Steel | Aluminum | Wood |

|---|---|---|---|---|

| Corrosion resistance | Excellent (inorganic corrosion-resistant) | Poor (rusts, requires coatings) | Good (but may corrode galvanically) | Poor (rot, insects) |

| Weight (for equal outside dimensions) | Low — typically 60–75% lighter than steel. | High | Lower than steel but higher than FRP | Low–medium |

| Electrical conductivity | Insulating (non-conductive) | Conductive | Conductive | Insulating |

| Maintenance | Very low | High (painting, treatment) | Medium (oxidation control) | High (sealants, rot control) |

| Cost (material) | Moderate; lifecycle cost often lower in corrosive environments. | Often lower initial cost but higher life-cycle cost | Often higher material cost | Low initial, high maintenance |

| Fabrication | Cut, drill, mechanical fasten, adhesive bonding | Weld, cut, bolt | Weld, bolt | Cut, join |

(Values are comparative — always perform project-specific life-cycle cost analysis.)

Installation & Fabrication Notes

Cutting: Use carbide or diamond blades; cut speeds and dust control precautions recommended.

Fastening: Use stainless or coated fasteners; avoid dissimilar metals in direct contact to prevent galvanic issues.

Joining: Mechanical fastening, adhesive bonding or structural inserts are common; avoid field welding (not applicable to FRP).

Thermal expansion: FRP has a higher coefficient of thermal expansion than steel; allow for expansion joints on long runs.

(Consult supplier installation guide for specific recommendations.)

Ordering & Customization

We offer:

Custom outer dimensions and wall thickness to engineered tolerances.

Choice of resin systems (standard polyester, chemical-resistant vinyl-ester, high-performance epoxy).

Standard and UV-stabilized gel-coat colors; special coatings on request.

Cut-to-length and pre-drilled fabrication services available for bulk orders.

E-A-T

Expertise: Pultrusion is an established manufacturing method; design relies on supplier D-sheets and ASTM testing (D638, D790, D695). Always use supplier certified test values in structural calculations.

Authoritativeness: Refer to manufacturer datasheets (e.g., Strongwell pultruded product specifications) and recognized materials databases for validated mechanical properties.

Trustworthiness: We recommend project QA steps: request lot test reports, request sample coupons for third-party test (if critical), and review supplier ISO/QC certifications. For handrails and public safety items, follow local building codes and supplier installation instructions.

FAQ

Q1: Is FRP square tube suitable for outdoor/UV exposure?

A: Yes — choose UV-stabilized gel-coat or factory UV-resistant resin systems for prolonged outdoor exposure. Confirm UV warranty with supplier.

Q2: Can FRP square tube be welded or threaded?

A: FRP is not welded like metals. Threaded metal inserts or mechanical fasteners and structural adhesives are standard practices for joining and creating threaded connections.

Q3: How do FRP tubes compare weight-wise to steel?

A: FRP profiles are substantially lighter — in many cases 60–75% lighter than comparable steel sections — easing installation and reducing structural support requirements.

Q4: Are there standard sizes I can order off-the-shelf?

A: Yes — suppliers typically stock popular sizes (1¼”, 1½”, 2″, 3″, 4″ with 1/8″ or 1/4″ walls) and standard lengths (8 ft, 20 ft). Custom sizes can be ordered.

Q5: What resin should I choose for chemical plants?

A: Vinyl-ester or specialized corrosion-resistant resin systems are recommended for aggressive chemical exposures; request chemical compatibility charts from the supplier.

Call to Action

For specification sheets, cut-to-length pricing, RL-grade datasheets, MOQ and lead-time, or to request a sample and third-party test reports, contact our sales team (replace with your contact info). We can provide engineered proposals, CAD sections and project MOQ pricing for bulk and repeat orders.