Product Overview

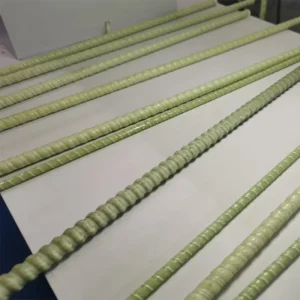

Pultruded Fiberglass Round Tubes are manufactured through a continuous pultrusion process that ensures high fiber content, uniform cross-sections, and consistent quality. Compared to steel, aluminum, or PVC, FRP/GRP round tubes offer excellent resistance to corrosion, impact, and chemicals, making them suitable for demanding environments.

Key Features & Advantages

High Strength-to-Weight Ratio – Stronger than steel at a fraction of the weight.

Corrosion Resistant – Withstands harsh chemicals, saltwater, and outdoor exposure.

Electrical Insulation – Non-conductive material, safe for electrical installations.

Dimensional Stability – Maintains shape and performance under temperature changes.

Low Maintenance – Reduces long-term costs compared to metal alternatives.

Specifications (Technical Data)

Available Sizes

Outer Diameter: 10mm – 200mm

Wall Thickness: 1.5mm – 10mm

Length: Customizable up to 6 meters

Material Properties

Fiber Content: ≥ 60%

Tensile Strength: ≥ 600 MPa

Flexural Strength: ≥ 500 MPa

Density: 1.9–2.0 g/cm³

Temperature Resistance: -40°C to +180°C

Product Data & Technical Documents

Download datasheets, chemical resistance charts, test reports and cutting templates.

Applications of Pultruded Fiberglass Round Tubes

Construction & Infrastructure – Bridges, walkways, supports, and handrails

Electrical Industry – Cable management, insulation tubes, and non-conductive supports

Marine & Offshore – Saltwater-resistant components for boats, docks, and offshore platforms

Industrial Equipment – Structural frames, pipelines, and reinforcement rods

Recreational Use – Tent poles, sports equipment, and composite reinforcements

Why Choose Our Pultruded Fiberglass Round Tubes?

Over 10 years of FRP/GRP manufacturing expertise

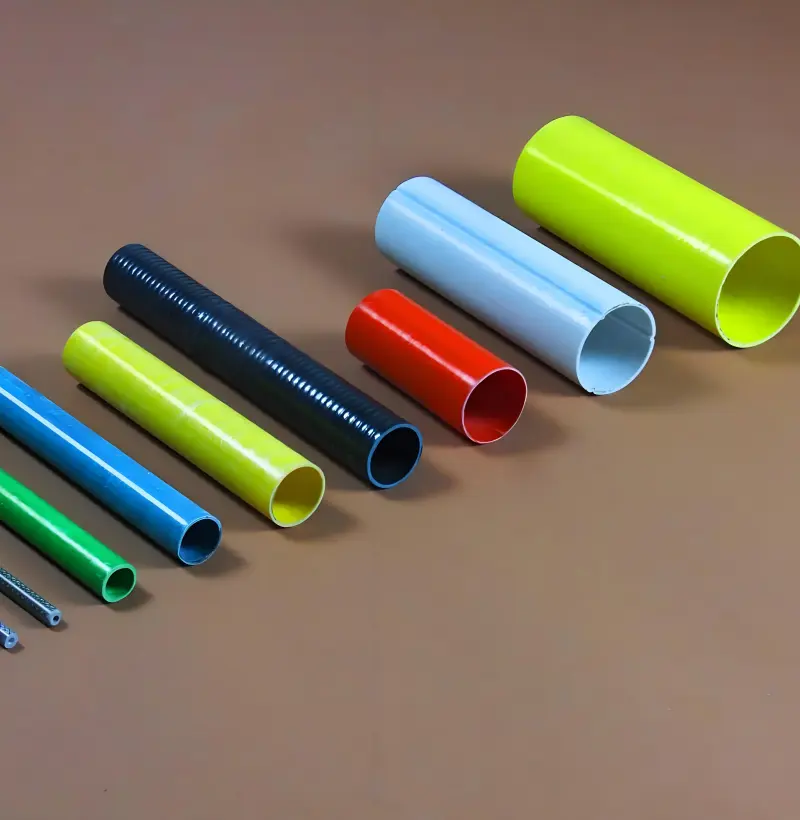

Custom dimensions and colors available

Strict quality control and ISO-certified production

Global supply capability with competitive pricing

FAQ – Frequently Asked Questions

Q1: What is the difference between pultruded fiberglass round tubes and molded fiberglass tubes?

A1: Pultruded tubes are produced in continuous lengths with uniform cross-sections, offering higher fiber content and strength, while molded tubes are typically used for complex shapes.

Q2: Can pultruded fiberglass round tubes replace steel or aluminum tubes?

A2: Yes, in many cases. They provide comparable strength while being lighter and corrosion-resistant, reducing long-term maintenance costs.

Q3: Are these tubes UV resistant for outdoor use?

A3: Yes, UV inhibitors can be added to enhance weather resistance, making them ideal for outdoor applications.

Q4: Can you produce customized sizes and colors?

A4: Absolutely. We offer tailored dimensions, wall thicknesses, and colors according to customer requirements.

Q5: What industries use pultruded fiberglass round tubes most frequently?

A5: Construction, marine, electrical, and industrial equipment are the top sectors using FRP/GRP tubes.