Product overview

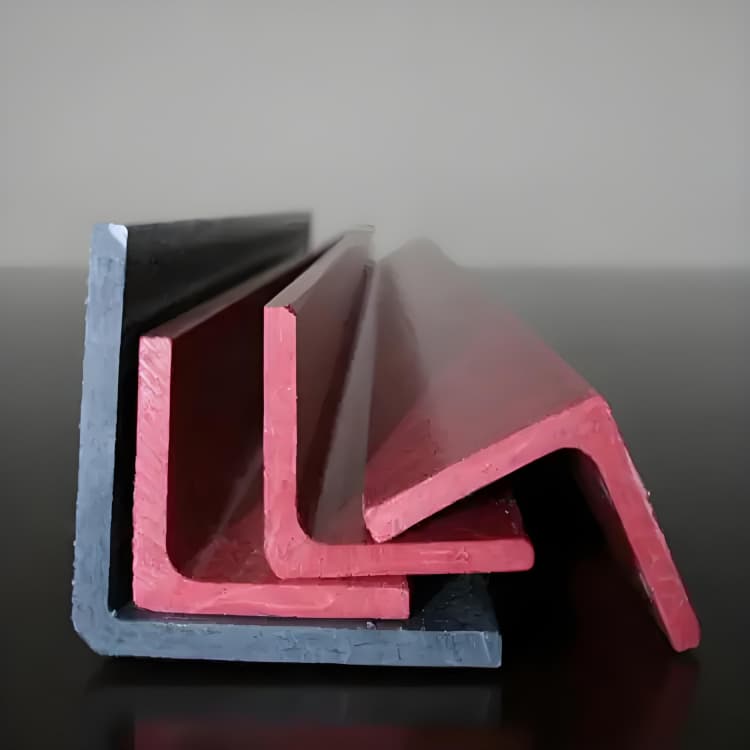

What it is A reinforced fiberglass angle is a pultruded FRP (fiber-reinforced plastic) L-section manufactured by aligning high-strength glass rovings and reinforcing mats in engineered orientations, impregnating them with a thermoset resin (polyester, vinyl-ester or epoxy), and curing through a heated die. The reinforcement architecture (extra rovings at the flange/web, higher fiber volume fraction, and optional hybrid fibers) is what differentiates a reinforced FRP angle from standard fiberglass angles — giving improved longitudinal stiffness, flexural strength and load-bearing capacity for structural uses.

A reinforced fiberglass angle is a pultruded FRP (fiber-reinforced plastic) L-section manufactured by aligning high-strength glass rovings and reinforcing mats in engineered orientations, impregnating them with a thermoset resin (polyester, vinyl-ester or epoxy), and curing through a heated die. The reinforcement architecture (extra rovings at the flange/web, higher fiber volume fraction, and optional hybrid fibers) is what differentiates a reinforced FRP angle from standard fiberglass angles — giving improved longitudinal stiffness, flexural strength and load-bearing capacity for structural uses.

How it differs from a standard fiberglass angle

Engineered rovings placement (more unidirectional fibers in directions that carry loads).

Higher fiber volume fraction and thicker flange/web options.

Option for hybrid layers (e.g., glass + specialty fillers) or higher-performance resins for chemical/heat resistance.

These choices increase allowable spans and reduce deflection under load compared to commodity fiberglass angle shapes.

Key features & buyer benefits

Enhanced structural performance — designed rovings and mat layup improve flexural and shear strength for real structural loading.

Corrosion & chemical resistance — choice of vinyl-ester or epoxy resins for aggressive environments.

Lightweight — significantly lower mass vs steel (easier handling & lower support costs).

Non-conductive & non-magnetic — safe for electrical/telecom installations.

Low life-cycle maintenance — no painting or cathodic protection required in most corrosive environments.

Typical technical specifications (reference ranges)

Important: Pultruded properties vary by manufacturer, resin system and reinforcement architecture. Below are typical, supplier-reported ranges used as design references — always request the manufacturer’s datasheet and, for critical projects, material test coupons or mill test reports.

Material & manufacturing

Process: Pultrusion with unidirectional rovings + stitched mat.

Common resins: Polyester (economical), Vinyl-ester (higher chemical resistance), Epoxy (high performance).

Standards for testing / reference: ASTM D638 (tensile), ASTM D790 (flexural), ASTM D695 (compressive), ASTM D2344 (interlaminar shear).

Representative mechanical property ranges (typical pultruded profile values)

Tensile strength (longitudinal): ~170–290 MPa (25–42 ksi) for pultruded profiles (dependent on fiber/resin mix).

Tensile/Flexural modulus (longitudinal): ~13–41 GPa (varies by construction; higher for rod/uni-roving heavy sections).

Density: ~1.7–2.0 g/cm³ (lighter than steel by volume).

Product Data & Technical Documents

Download datasheets, chemical resistance charts, test reports and cutting templates.

Common sizes & stocked options

Below are industry-stock examples used by pultruders and distributors — these reflect real, purchasable profiles (confirm stock/weights with supplier).

| Size (Leg × Leg) | Typical Wall/Thickness | Typical stocked length | Example weight / ft (approx.) |

|---|---|---|---|

| 25 × 25 mm (≈1″×1″) | 3–4 mm (1/8″–5/32″) | 2.5–6 m (8–20 ft) | ~0.19 lb/ft (1″×1″ example). |

| 38 × 38 mm (1½”×1½”) | 4–6 mm | 2.5–6 m | common stocked size. |

| 50 × 50 mm (2″×2″) | 4–6 mm (3/16″–1/4″) | 2.5–6 m | 0.75–1.44 lb/ft (varies by wall). |

| 75 × 75 mm (3″×3″) | 6–8 mm | 2.5–6 m | heavy structural angle (example from Fiberline). |

We offer on-site cutting, pre-drilling and custom flange widths/thicknesses for engineered orders.

Typical applications

Industrial structural supports, brackets & gussets where corrosion and weight matter.

Walkways, handrails & guardrails in chemical plants, wastewater and marine facilities.

Telecom masts & electrical insulating supports — non-conductive, RF-transparent options.

OEM frames, machine guards & fixtures requiring precision profiles and predictable stiffness.

(If your project requires calculated load and deflection limits, request supplier span tables and third-party test coupons.)

Why choose reinforced FRP angle

Engineered fiber architecture — targeted rovings increase moment capacity at flanges and webs (reduces deflection vs commodity angle).

Higher allowable spans — thicker flanges and controlled fiber orientation extend unsupported lengths for structural brackets and rails.

Selectable resin systems — upgrade to vinyl-ester/epoxy for plants handling solvents/acids.

Quality traceability — manufactured to pultrusion QC processes and tested per ASTM methods; suitable for engineered spec packages.

Comparison table: Reinforced FRP Angle vs Steel / Standard Fiberglass / Aluminum

| Property | Reinforced FRP Angle | Carbon Steel Angle | Standard Fiberglass Angle | Aluminum Angle |

|---|---|---|---|---|

| Corrosion resistance | Excellent (with vinyl-ester/epoxy options). | Poor without coatings | Good but lower strength than reinforced FRP. | Good, but galvanic concerns with dissimilar metals |

| Structural stiffness (for same dimensions) | High (engineered rovings; stronger than commodity FRP) | Very high | Moderate (commodity FRP has lower fiber content) | High (but heavier than FRP per strength ratio) |

| Weight | Low (60–75% lighter than steel by weight for same geometry). | High | Low | Medium |

| Electrical conductivity | Insulating (non-conductive). | Conductive | Insulating | Conductive |

| Maintenance | Very low | High (paint, corrosion control) | Low | Medium |

(Comparison based on typical properties — always perform project-specific engineering and life-cycle cost analysis.)

Installation & fabrication guidance

Cutting: Use carbide or diamond blades; control dust and use PPE.

Fastening: Prefer stainless steel bolts or non-metallic inserts; use metal inserts only where necessary, and consider isolating plates for dissimilar metals.

Joining: Mechanical fastening, adhesive bonding, and custom insert systems are common — avoid attempting metal-style welding.

Thermal considerations: Allow for thermal expansion in long runs — pultruded FRP expands more than steel.

E-A-T

Expertise: Reinforced FRP angle product and design rely on pultrusion know-how and validated test methods (ASTM D790, D638 etc.). For engineered projects, provide supplier D-sheets and laminate schedules for review.

Authoritativeness: Use supplier certificates, ISO/QC documentation and independent test reports when specifying in bid documents — request them during RFQ stage.

Trustworthiness: We recommend (1) requesting a material test report for the delivered lot, (2) ordering sample coupons for structural verification if loads are critical, and (3) keeping traceable lot numbers and manufacturer certifications in project files.

FAQ

Q1 — Is “reinforced FRP angle” strong enough to replace steel for load-bearing brackets?

A: In many corrosive or weight-sensitive applications, yes — reinforced FRP angles with engineered rovings and higher fiber content can meet design load requirements. Always compare supplier span tables and D-sheet values to your load/deflection criteria and consult a structural engineer for safety-critical uses.

Q2 — What resin should I choose for a chemical processing plant?

A: Vinyl-ester or specialty epoxy systems offer superior chemical and thermal resistance vs standard polyester; request a chemical compatibility chart from the supplier.

Q3 — Do you stock custom flange widths or thicker walls?

A: Most pultruders offer custom flange/web dimensions and wall thicknesses to suit engineered orders; lead times and MOQ depend on production scheduling.

Q4 — Can I get pre-drilled or cut-to-length pieces?

A: Yes — many suppliers provide cut-to-length, pre-drilling and secondary fabrication services for bulk orders. Confirm tolerances and shipping lengths.

Q5 — How is fire performance?

A: Fire performance depends on resin and fillers. For fire-sensitive projects, request supplier E-class or ASTM E84 surface burning characteristics and the required fire retardant formulations.

Ordering & next steps

If you need: product datasheets, span/deflection tables, chemical compatibility charts, cut-to-length pricing, or sample coupons for testing — request an RFQ with: required size (leg × leg × thickness), resin preference (polyester/vinyl-ester/epoxy), length(s), quantity, and any secondary services (cutting, drilling, inserts). We’ll return a formal quote, lead time and certified datasheets.