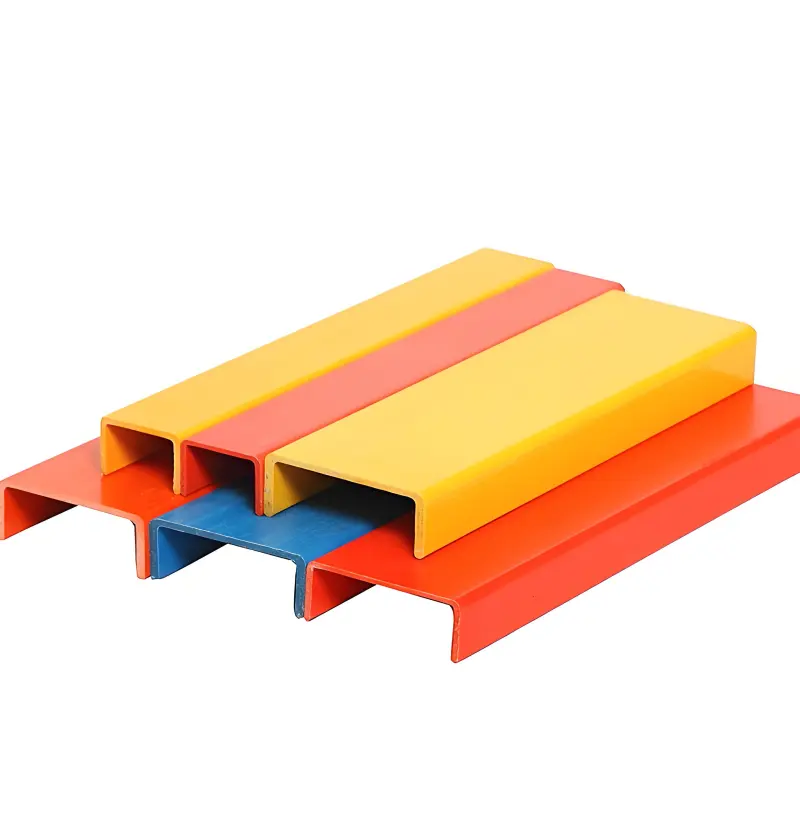

In the world of industrial construction and infrastructure, FRP U Channels and FRP C Channels (also known as Fiberglass U Channels and Fiberglass C Channels) have emerged as game-changing alternatives to traditional steel and aluminum profiles. Engineered for durability, lightweight performance, and unmatched corrosion resistance, these composite profiles are redefining standards across industries.

What Are FRP U/C Channels?

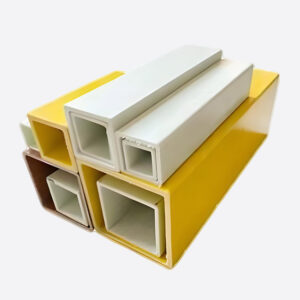

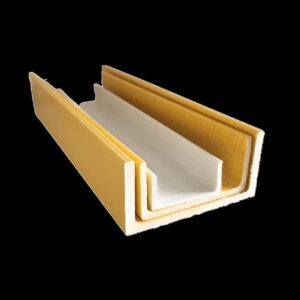

FRP U Channels and FRP C Channels are structural profiles molded from fiberglass-reinforced polymer (FRP). The Fiberglass U Channel features a U-shaped cross-section, while the Fiberglass C Channel has a C-shaped design, both optimized for load-bearing applications in harsh environments. Their unique geometry provides exceptional strength-to-weight ratios, making them ideal for frameworks, supports, and edge protection systems.

Key Advantages

Corrosion Resistance

Unlike steel, FRP U Channels and FRP C Channels resist rust, chemicals, and moisture. They thrive in corrosive settings like chemical plants, marine platforms, and wastewater facilities.Lightweight & High Strength

Weighing just 1/4 of steel, Fiberglass U Channels reduce installation time and structural load while maintaining comparable tensile strength (up to 300 MPa).Non-Conductive & Non-Sparking

Safe for electrical hazardous areas (e.g., oil refineries) where metal poses ignition risks.Low Maintenance

No painting or galvanizing required. UV-stabilized resin ensures long-term outdoor performance.

Product Data & Technical Documents

Download datasheets, chemical resistance charts, test reports and cutting templates.

Applications

- Chemical Processing: Frame supports for acid storage tanks (using FRP U Channels for edge reinforcement).

- Marine Infrastructure: Dock fender systems and seawall bracing with Fiberglass C Channels.

- Electrical Utilities: Cable trays and substation structures in non-conductive zones.

- Architecture: Lightweight roof trusses and façade frameworks.

Why Choose FRP U Channels Over Steel?

FRP U Channels outperform steel in three critical areas:

- Lifespan: 30+ years in corrosive environments vs. steel’s 5-10 years.

- Installation: Bolt-free adhesive bonding options for seamless assembly.

- Cost Efficiency: Lower lifecycle costs due to zero maintenance.

Customization Options

Tailor FRP U Channels and Fiberglass C Channels to your project needs:

- Resin Types: Phenolic for fire resistance or polyester for cost-sensitive projects.

- Surface Textures: Grit-coated or smooth finishes.

- Colors: Standard green, grey, or custom RAL codes.

Conclusion

For engineers seeking corrosion-proof, lightweight, and sustainable structural solutions, FRP U Channels and FRP C Channels deliver unmatched versatility. Whether reinforcing a chemical plant or building a coastal walkway, these profiles ensure decades of reliable performance.

Upgrade to FRP U/C Channels today—where innovation meets endurance.