What Are FRP Rock Bolts?

FRP Rock Bolts are structural reinforcements manufactured from fiber reinforced polymer composites. They are designed to secure unstable rock masses, prevent collapse, and enhance ground stability. Compared to conventional steel bolts, FRP bolts offer long-lasting durability, minimal maintenance, and resistance to aggressive chemicals, water, and electrochemical corrosion.

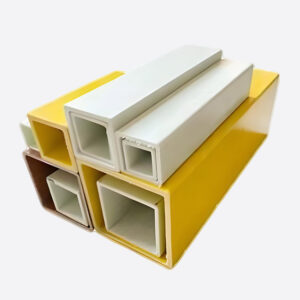

Key Features of Fiberglass Rock Bolts

Corrosion Resistance: Performs reliably in acidic, alkaline, and saline environments.

High Tensile Strength: Comparable to steel while being significantly lighter.

Lightweight Design: Easy to transport and install, reducing labor costs.

Non-Conductive: Safe for use in electrical and electromagnetic-sensitive zones.

Fire & Thermal Resistance: Maintains structural integrity under high temperatures.

Cost-Effective: Longer service life reduces replacement frequency.

Technical Specifications

| Parameter | Value Range / Option | Notes |

|---|---|---|

| Material | Fiber Reinforced Polymer (FRP) | E-glass / Carbon Fiber Reinforcement |

| Diameter | 18mm – 32mm | Custom sizes available |

| Length | 1.2m – 3.0m | Longer bolts upon request |

| Tensile Strength | ≥ 800 MPa | High load-bearing performance |

| Elastic Modulus | 40 – 60 GPa | Ensures controlled deformation |

| Surface Coating | Sanded / Ribbed | Improves bonding with resin/grout |

| Service Life | 50+ years | Longer than conventional steel bolts |

Applications of FRP Rock Bolts

Mining Industry

Used to reinforce underground mines, preventing rock falls and maintaining tunnel safety.

Tunneling Projects

Applied in metro tunnels, hydro tunnels, and road tunnels where corrosion resistance is critical.

Slope Stabilization

Secures unstable rock masses in highways, railways, and open-pit mines.

Marine & Chemical Environments

Ideal for projects exposed to seawater or chemical corrosion.

Advantages of Choosing Fiberglass Rock Bolts

Extended lifespan compared to steel bolts.

Reduced transportation and installation costs due to lightweight nature.

Enhanced worker safety with non-conductive and spark-free properties.

Environmentally friendly with reduced maintenance requirements.

Customizable design tailored to project specifications.

Why Partner With Us for GRP Rock Bolts?

We are a trusted manufacturer with extensive experience in composite ground support systems. Our FRP rock bolts are produced under strict quality control, tested for tensile strength, load-bearing performance, and long-term durability. We also provide customized solutions to meet unique mining, tunneling, or slope stabilization requirements.

FAQ – FRP Rock Bolts

Q1: How do fiberglass rock bolts compare with steel bolts in strength?

A1: FRP rock bolts deliver tensile strength on par with steel, while offering superior corrosion resistance and lower weight.

Q2: Can fiberglass Rock Bolts be used in high-moisture or chemical-rich environments?

A2: Yes, they are designed to resist moisture, acid, alkali, and salt corrosion, making them ideal for tunnels, mines, and coastal projects.

Q3: Are FRP rock bolts customizable for different project needs?

A3: Absolutely. We offer various diameters, lengths, and surface treatments based on project requirements.

Q4: What is the typical service life of fiberglass rock bolts?

A4: With proper installation, GRP Rock Bolts can last over 50 years, outperforming conventional steel bolts.