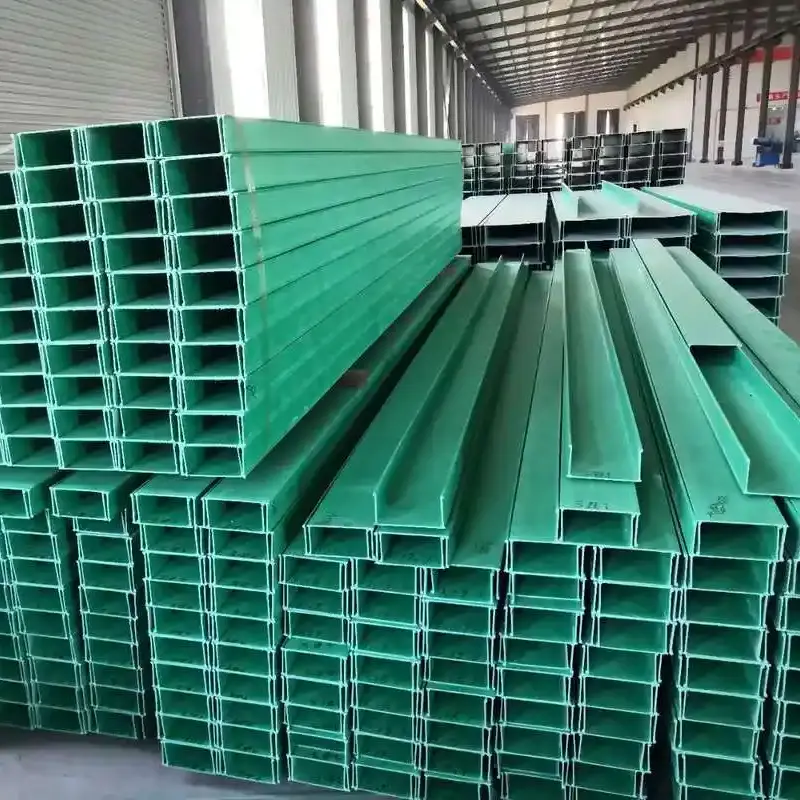

Industrial-Grade Protection for Critical Infrastructure

Our FRP cable trays provide superior cable organization while resisting harsh chemicals, moisture, and extreme temperatures. Commonly specified as fiberglass cable trays in petrochemical plants, wastewater treatment facilities, and coastal power stations, these non-conductive systems ensure long-term reliability where metal alternatives fail.

Why Our FRP Trays Outperform Competitors

Lifetime corrosion resistance (No rust even in 95% humidity)

- 50% lighter than steel with equal load capacity (ASTM D3916 certified)

- Flame-retardant formulations meeting UL 94 V-0 standards

- Custom fabrication available for bends, tees, and risers within 72 hours

Proven Performance in Demanding Environments

Proven Performance in Demanding Environments

A recent offshore wind farm project utilized our 6″ wide ladder-type FRP trays across 3.2km of turbine connections, surviving salt spray exposure where galvanized steel corroded within 18 months. Other success stories include:

• Chemical plant in Texas: 8-year maintenance-free operation

• Dubai Metro expansion: 12,000 linear meters installed

• Norwegian fish processing facility: Withstands daily acid washdowns

Product Data & Technical Documents

Download datasheets, chemical resistance charts, test reports and cutting templates.

Upgrade Your Cable Management Today

Request project-specific load calculations and material samples – our engineers will recommend the optimal FRP tray configuration (trough/ladder/grid) for your application within 24 hours.

| Material | Support and hanger span mm | Safe working load | Calorific value(≤)mm | ||

| Side height 100mm | Side height 150mm | Side height 2000mm | |||

| FRP | 2000 | 550 | 1100 | 1750 | 10 |

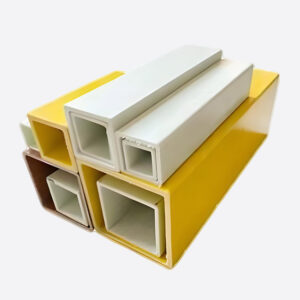

- Products size

- Trough-type FRP cable tray: common specification, thickness and weight

| Size (mm) | Thickness (mm) | Weight (kg) | Size (mm) | Thickness (mm) | Weight (kg) |

| 50*50 | 2.5/2.6 | 1.2 | 300*150 | 3.8/3.4 | 6.0 |

| 100*50 | 3.0/3.0 | 1.9 | 300*200 | 4.0/3.4 | 7.0 |

| 100*100 | 3.0/3.0 | 2.4 | 400*100 | 4.0/3.8 | 7.1 |

| 150*100 | 3.0/3.0 | 3.1 | 400*150 | 4.0/3.8 | 8.0 |

| 200*100 | 3.0/3.0 | 3.8 | 400*200 | 4.5/3.8 | 9.8 |

| 200*150 | 3.3/3.0 | 4.5 | 500*200 | 4.5/4.2 | 11.9 |

| 200*200 | 3.6/3.0 | 5.4 | 600*150 | 4.7/4.0 | 13 |

| 250*150 | 4.0*3.2 | 5.7 | 600*200 | 5.0/4.0 | 13.8 |

| 300*100 | 3.5/3.4 | 5.2 |

- Ladder-type FRP cable tray: common specification, thickness and weight

| Size (mm) | Thickness (mm) | Weight (kg) | Size (mm) | Thickness (mm) | Weight (kg) |

| 200*100 | 3.6/3.0 | 4.5 | 500*100 | 3.6/3.5 | 7.6 |

| 200*150 | 3.9/3.0 | 5.6 | 500*200 | 3.9/3.5 | 9.1 |

| 200*200 | 3.9/3.0 | 6.0 | 600*100 | 3.6/4.0 | 9.0 |

| 300*100 | 3.6/3.4 | 5.5 | 600*150 | 3.9/4.0 | 10 |

| 300*150 | 3.9/3.4 | 6.6 | 600*200 | 3.9/4.0 | 10.5 |

| 300*200 | 3.9/3.4 | 7.0 | 800*100 | 3.6/4.8 | 12 |

| 400*100 | 3.6/3.5 | 6.5 | 800*150 | 3.9/4.8 | 13.1 |

| 400*150 | 3.9/3.5 | 7.5 | 800*200 | 3.9/4.8 | 13.5 |

| 400*200 | 3.9/3.5 | 8.0 |

- TEST REPORT

Samples number: 20210608434 Sample size: PCT250x150x2mm

| Test items | technical requirement | Test result | ||

| Test value | Single conclusion | |||

| Appearance quality | The surface of the product shall be flat and smooth, with uniform color, and shall be free of wrinkles, cracks, particles, glue flow, resin peeling, fiber exposure and surface sticking. | Meet the requirements | qualified | |

| The glue content is uniform, the curing is stable, and there is no delamination. The accumulated area of bubbles on the surface of a single product shall not be greater than 100mm2/m2, and the maximum area of a single bubble shall not be greater than 15mm2. | ||||

| Structure size mm | Width | 250±2 | 250 | qualified |

| Height | 150±2 | 150 | qualified | |

| Thickness | 2(0, +0.2) | 2.2 | qualified | |

| tensile strength Mpa | direction | ≥560 | 897 | qualified |

| bending strength Mpa | direction | ≥270 | 1237 | qualified |

| impact strength kJ/m2 | ≥200 | 415 | qualified | |

| Barcol hardness | ≥45 | 56 | qualified | |

| Density g/cm3 | ≥1.9 | 2.1 | qualified | |

| Load deformation temperature ℃ | ≥150 | >160 | qualified | |

| Oxygen index % | ≥28 | 28 | qualified | |