Product Description

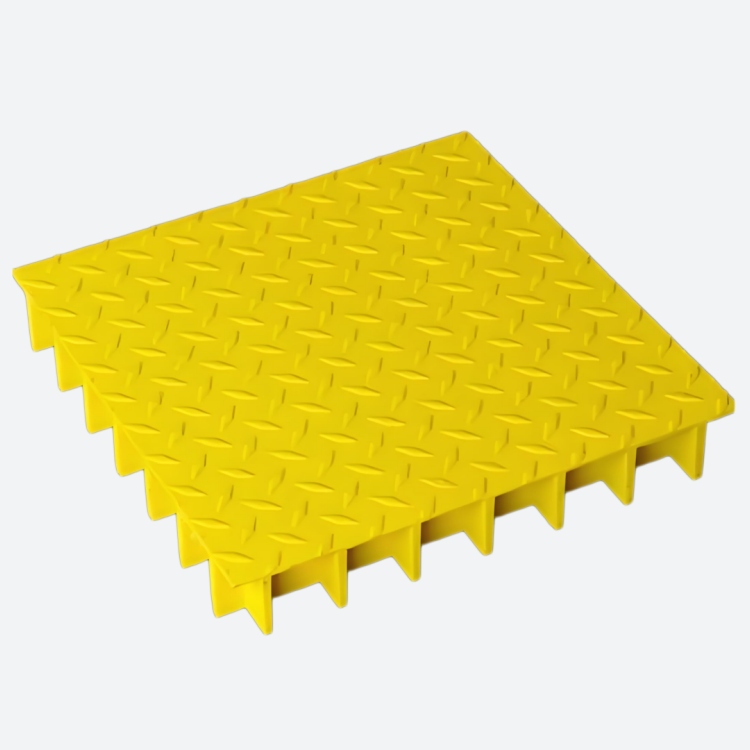

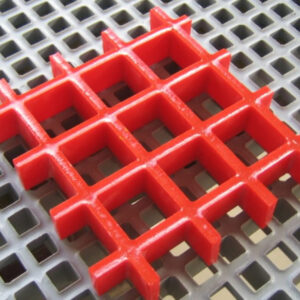

Covered fiberglass grating is made from a composite of fiberglass and resin with a full coverage top layer. The solid surface prevents small objects, liquids, and debris from falling through, making it ideal for environments requiring cleanliness and safety. Its excellent strength-to-weight ratio and resistance to chemicals, moisture, and UV make it a long-lasting choice for demanding applications.

Specifications

| Parameter | Value / Options |

|---|---|

| Material | Fiberglass Reinforced Plastic (FRP) |

| Resin Type | Isophthalic, Vinyl Ester, Phenolic |

| Top Surface | Solid covered, anti-slip finish |

| Panel Thickness | 25mm, 38mm (custom available) |

| Panel Size | 1000×3000mm, 1220×3660mm (custom available) |

| Color Options | Yellow, Grey, Green, Custom |

| Load Capacity | Up to 500 kg/m² |

| Fire Resistance | ASTM E84 Class 1 |

| Standards | ASTM, ISO, EN compliant |

Key Features & Advantages

Slip-Resistant Surface – Safe for wet, oily, or high-traffic areas.

Corrosion & Chemical Resistance – Ideal for marine, chemical, and wastewater plants.

Lightweight Yet Strong – Easier installation compared to steel grating.

Non-Conductive – Safe for electrical environments.

Low Maintenance – No painting or galvanizing required.

Customizable Sizes & Colors – Fit any project requirements.

Applications

Marine & Offshore Platforms – Decking, walkways, and docks.

Chemical Plants – Spill containment areas, tank covers.

Food & Beverage Industry – Hygienic flooring with easy cleaning.

Wastewater Treatment Plants – Walkways and maintenance platforms.

Industrial Facilities – Equipment flooring, trench covers.

Why Choose Our Covered Fiberglass Grating

Over 15 years of manufacturing expertise.

Exported to 40+ countries with proven performance in extreme conditions.

Strict quality control and compliance with international standards.

Fast delivery and flexible customization.

FAQ

Q1: What is the difference between covered fiberglass grating and regular FRP grating?

A: Covered grating has a solid top surface, preventing spills, debris, and small tools from falling through, while offering a smoother walking surface.

Q2: Can covered fiberglass grating be customized in size and color?

A: Yes, we offer custom dimensions, thicknesses, and color options to meet your project requirements.

Q3: Is it suitable for outdoor use?

A: Absolutely. It has UV protection and weather resistance, making it ideal for outdoor and marine environments.

Q4: How long does it last?

A: With proper installation and minimal maintenance, it can last 20+ years in harsh environments.