Short product intro

⚡ Conductive top FRP grating dissipates static safely via a molded carbon surface (10⁴–10⁶ Ω/sq), combining ESD protection, corrosion resistance and lightweight strength for hazardous-area walkways.

Alternative Names

Alternative Names

Anti-Static FRP Grating

ESD-Safe Fiberglass Grating

Electrically Conductive Composite Grating

Spark-Resistant Flooring

Conductive Fibreglass Grating / Conductive GRP Grating

Key Material Features

⚡ Conductive Surface — Molded or secondarily applied carbon-enhanced or metal-coated strands form a conductive top layer; typical surface resistivity: 10⁴–10⁶ Ω/sq, preventing static build-up and allowing safe dissipation when grounded.

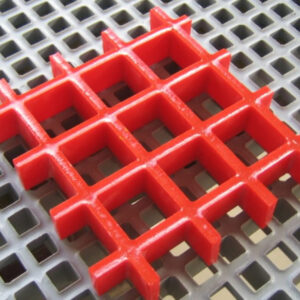

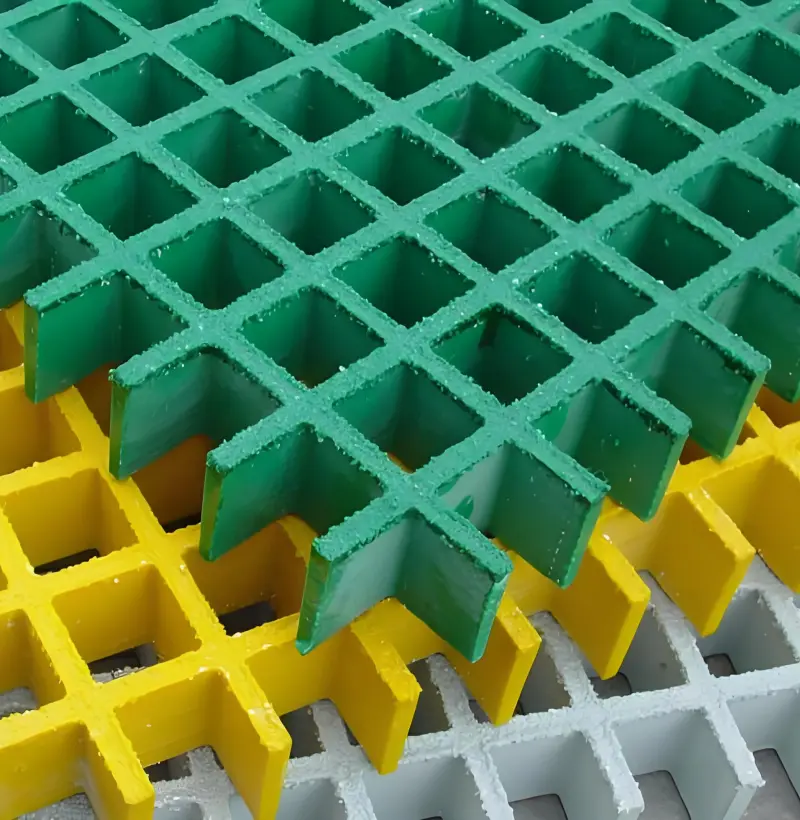

⚡ Molded FRP Construction — Maintains the mechanical and corrosion-resistant benefits of molded fiberglass grating.

⚡ Explosion-Safe — Suitable for hazardous zones where sparks could ignite flammable atmospheres (use in accordance with local hazardous-area regulations).

⚡ Corrosion Immunity — Excellent resistance to H₂S, hydrocarbons, saltwater, and many industrial chemicals.

⚡ Lightweight & High Strength — A fraction of steel’s weight with substantial load capacity.

⚡ Customizable — Slip-resistant textured surfaces, UV-stable color options, and fire-retardant treatments available (e.g., ASTM E84 Class A options).

Typical Specifications

| Item | Specification |

|---|---|

| Panel Size | 1 m × 2.5 m (standard; cut-to-size available) |

| Thickness | 30–40 mm (depending on load & span) |

| Surface Resistivity | 10⁴ – 10⁶ Ω/sq (surface resistivity) |

| Electrical Resistance | < 26 kΩ / ft (when properly grounded) |

| Load Capacity | 5 tons / m² (application-specific — verify in design) |

| Temperature Range | −40 °C to +150 °C |

| Surface | Molded black conductive safety surface (textured) |

Note: Values above reflect typical ranges. Final selection should be validated against project-specific load, span, grounding, and code requirements.

Product Data & Technical Documents

Download datasheets, chemical resistance charts, test reports and cutting templates.

Applications

Oil & Gas — Refinery walkways, LNG plant platforms, loading mezzanines.

Petrochemical & Chemical Plants — Processing platforms in H₂S or hydrocarbon service.

Electronics & Semiconductor Manufacturing — ESD-controlled work areas, cleanroom perimeter paths.

Pharmaceuticals — Areas with ESD-sensitive instrumentation.

Mining & Tunneling — Ventilation galleries and walkways in methane-prone zones.

Data Centers & Server Rooms — Raised flooring or access platforms requiring static control.

Benefits — Why Choose Conductive Top FRP Grating?

🔋 Enhanced Safety — Reduces risk of static sparks that can ignite flammable atmospheres.

🔋 Long Service Life — Superior corrosion resistance compared with metal gratings in aggressive environments.

🔋 Lower Life-Cycle Cost — No galvanic corrosion, reduced maintenance and replacement cost versus steel.

🔋 Lightweight & Easy to Install — Simplifies handling, reduces support structure loads, and shortens installation time.

🔋 Customizable Performance — Available with different anti-slip textures, fire retardant and UV-stabilized color options.

Case Study — Petrochemical Facility, Texas (2026)

Project: Hydrogen sulfide (H₂S) processing zone walkways

Scope: 500 m² of conductive molded FRP grating with grounded conductive network

Outcome: Eliminated measurable static-induced sparking events in the licensed zone, reduced unscheduled downtime by ~40%, and supported compliance with site ESD and safety policies.

Compliance & Standards

IEC 61340-5-1 — ESD protection (general ESD control guidance)

API RP 2003 — Static electricity control for hydrocarbon processing

ATEX Directive 2014/34/EU — Equipment and protective systems for potentially explosive atmospheres (site classification and installation practices apply)

Relevant local codes and client specifications should be consulted for hazardous area installations.

Installation & Grounding

Ensure a continuous, low-resistance grounding path from the conductive top layer to facility earth ground.

Design grounding and bonding per project electrical and safety engineers’ specifications and applicable codes.

Use conductive clips or bonding straps at recommended intervals and verify continuity with a megohmmeter or surface resistivity tester after installation.

FAQ

Q1: How does conductive FRP differ from regular FRP grating?

A: Conductive FRP has a conductive top layer (carbon or metal treatment) that allows static charges to bleed to ground. Regular FRP is electrically insulating and does not provide this ESD protection.

Q2: What surface resistivity is considered “anti-static” for industrial use?

A: Anti-static/ESD surfaces commonly target surface resistivity in the 10⁴–10⁶ Ω/sq range. Exact requirements depend on the application — consult your ESD standard or engineer.

Q3: Can conductive FRP be used in explosive atmospheres?

A: Yes — when correctly specified, grounded, and installed per hazardous-area requirements and site safety procedures. ATEX/IEC zone rules and local regulations must be followed.

Q4: Is the conductive surface durable? Will it wear off?

A: The conductive surface is molded or secondarily applied as a robust safety layer. Wear depends on traffic, abrasion, and chemical exposure; periodic inspection and maintenance are recommended.

Q5: Can I cut or drill the panels on site?

A: Yes. Panels can be cut/drilled with standard fiberglass cutting tools. After cutting, edges should be finished per manufacturer guidance and any conductive continuity at cut interfaces verified if required.

Alternative Names

Alternative Names