— Hongwo Workshop Engineer · Liu Feng

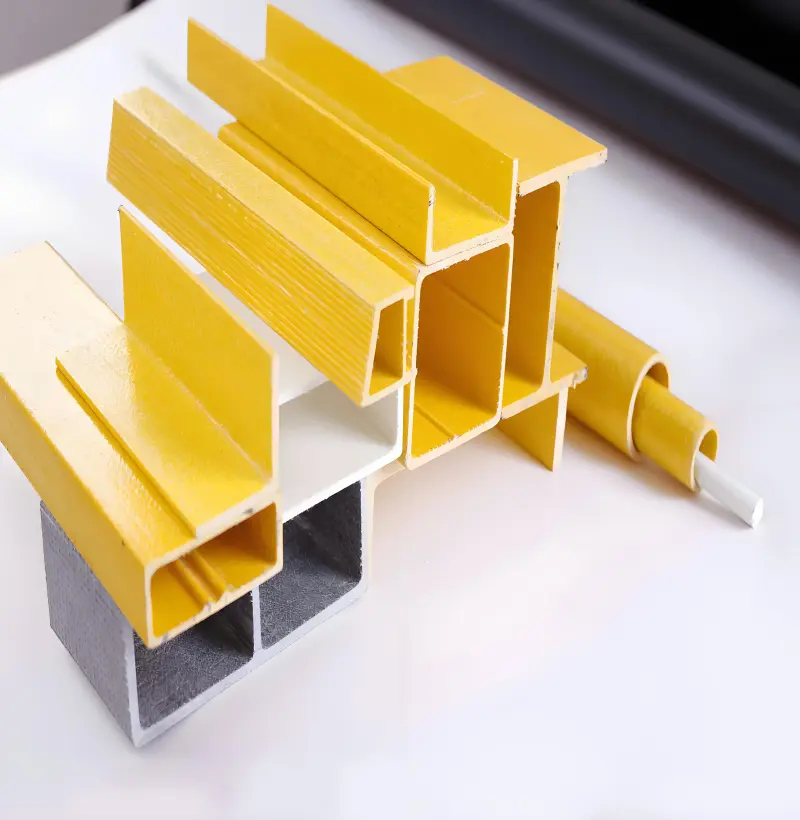

A pultrusion line operates non-stop for 24 hours. Glass roving moves through a resin bath, then enters the die. It reaches a thermal peak of 150°C. Finally, someone pulls the pultruded fiberglass rectangular tubes out like a 140-meter noodle. Many people ask: what can this stuff actually do? Here are ten field-proven applications from 2025. I’ll cover each section’s usual choice, role, installation method, and on-site performance. All data come from shop tests and site feedback — no empty claims.

A pultrusion line operates non-stop for 24 hours. Glass roving moves through a resin bath, then enters the die. It reaches a thermal peak of 150°C. Finally, someone pulls the pultruded fiberglass rectangular tubes out like a 140-meter noodle. Many people ask: what can this stuff actually do? Here are ten field-proven applications from 2025. I’ll cover each section’s usual choice, role, installation method, and on-site performance. All data come from shop tests and site feedback — no empty claims.

(Primary keyword: Applications of FRP Pultruded Rectangular Tubes. Also used in text: pultruded fiberglass rectangular tube, pultruded GRP rectangular tube, pultruded FRP box section, FRP pultruded rectangular profile, and pultruded composite rectangular tube.)

1. Petrochemical utility rack supports

Typical section & material: 200 × 100 × 6 mm; vinyl-ester resin; glass-fibre content 68 wt%. Role: Support DN250 chemical piping, design load 4.0 kN/m.

Installation:

Stainless steel clamp plates

M16 bolts

4.0 m span

Welders attach end plates to steel column transition pieces.

On-site performance: Ningbo Daxie Island project (commissioned 2022). Quarterly salt-spray checks show strength retention of 96% and no delamination.

2. Offshore wind farm inspection walkway

Typical section & material: 250 × 50 × 8 mm; quartz-sand anti-slip surface; LOI (oxygen index) 32. Role: Replace hot-dip galvanized grating. Reduce weight by 65%. It is a maintenance walkway rated for typhoon class 12.

Installation:

Side C-channel plug-in connections

No on-site welding.

Two workers can lay 120 m per day.

On-site performance: Guangdong Yangjiang project (2023). During Typhoon “Haikui,” the greatest mid-span deflection was 9 mm. After unloading, there was no residual deformation.

3. Lithium battery plant flue/exhaust rectangular ducts.

Typical section & material: 150 × 75 × 5 mm; phenolic resin system; smoke density Ds10 ≤ 50. Role: Rectangular duct framing: HF-resistant and electrically insulating. Installation: Corner adhesives + rivets; flanges wrapped with conductive copper foil for grounding. On-site performance: Power battery factory in Changzhou (2024). Continuous acid-mist operation means no blistering on the outer wall. The inner fibers remain protected and are not exposed.

4. Triple-rail metro protective cover (third-rail shroud)

Typical section & material: 120 × 80 × 4 mm. It features a non-magnetic formulation. The relative permeability μr is less than 1.02. **Role:** Covers the 750 V DC third rail. It stops accidental contact, keeps snow out, and shields against bird strikes. Installation: Snap-clip suspension; thermal expansion gap of 15 mm every 12 m. On-site performance: Beijing Metro Line 19 (south section), opened in 2023. Low-temperature (-20°C) cold-bending impact retained 87% strength; no brittle fracture.

5. Sewage treatment plant operational platforms

Typical section & material: 100 × 50 × 4 mm; orthophthalic polyester resin; grooved surface with Ra ~6.3 (anti-slip). Role: Replace traditional carbon-steel checker plate; resistant to H₂S and humid environments.

Installation:

I-beam spacing: 1.2 m

Workers secure tubes to beams using angle brackets and bolts.

Platform live load: 3.5 kN/m².

On-site performance: Wuhan Beihu Sewage Plant (2024). After one year, Barcol hardness retention is at 93%. There are no signs of electrochemical corrosion.

6. PV single-axis tracker main beams

Typical section & material: 180 × 60 × 5 mm; axial modulus ≥ 45 GPa; interlaminar shear ≥ 35 MPa. Role: 20 MW mountain PV farm; single beam length 30 m; beam rotates with the drive reducer to track the sun. Installation: Metal end plates + sleeve + flange bolts; driven torque 2.5 kN·m. On-site performance: Huaping, Yunnan (2025). Wind-tunnel test to 45 m/s; largest end rotation 0.18°, within 0.25° limit.

7. High-voltage cable bridge/support

Typical section and material: 200 × 150 × 6 mm. They change resin with ATH (aluminum trihydroxide). LOI is 34. Role: Support for 110 kV submarine cable landfall section — insulating, non-magnetic, flame-retardant.

Installation:

We space the FRP support columns 2.0 m apart.

Workers bolt tubular beams to column angle plates.

On-site performance: Pingtan, Fujian (2024). Short-circuit test 31.5 kA/1 s; surface temperature rise 18 °C; no deformation.

8. Cold-chain logistics racking beams

Typical section & material: 120 × 60 × 4 mm; low-temperature toughened epoxy; impact energy at −40°C ≥ 180 kJ/m². Role: Automated cold storage at −25°C, carrying 1.5 t pallets.

Installation:

Hook-clip fastening.

Racking boards connect to beams without bolts.

Assembly and disassembly take 10 seconds or less.

On-site performance: Fengxian cold storage, Shanghai (2025).

One year and 1.2 million fork cycles showed:

Beam mid-span deflection increased by less than 0.3 mm.

No interlaminar cracking occurred.

9. Flue-gas desulfurization (FGD) spray layer support

Typical section & material: 250 × 100 × 8 mm. It includes biaxial fabric layers. There’s also inner UD roving to boost circumferential stiffness.

Role: Support three levels of alloy spray piping with 6.0 m spans. The internal temperature is about 90 °C.

Installation: Use bonded joints and wrapped local reinforcement. The site does not allow any hot work.

On-site performance: Guoneng Anqing Power Plant (2023). Offline inspection showed intact adhesive seams with no delamination or blistering.

10. Rapid-deploy emergency bridge (modular)

Typical section and material: 300 × 200 × 10 mm. We add web stiffeners. The single-beam ultimate bending moment is ≥ 120 kN·m. Role: Emergency crossing over a 30 m gorge; allowable axle load per vehicle is 60 t.

Installation: Modular male/female joints use bolted pre-tensioning serrated plates. They can open to traffic in four hours.

On-site performance: Wuzhou emergency drill, Guangxi (2024). Tested to 1.3× the design load. Mid-span deflection is L/285. It shows full elastic return after unloading. It meets the emergency bridge standard GB/T 5058.

Conclusion

Pultruded fiberglass rectangular tubes aren’t a one-size-fits-all solution. With the right resin system and smart nodes, they form a strong backbone for industrial uses. Hongwo operates 32 pultrusion lines. They also handle online deburring and QR code traceability. Plus, they provide a mechanical test report with each tube. Share your loading conditions and spans. In ten minutes, we’ll provide the best section and node details. This helps you save money and ensures decades of reliable service.