Overview

Overview

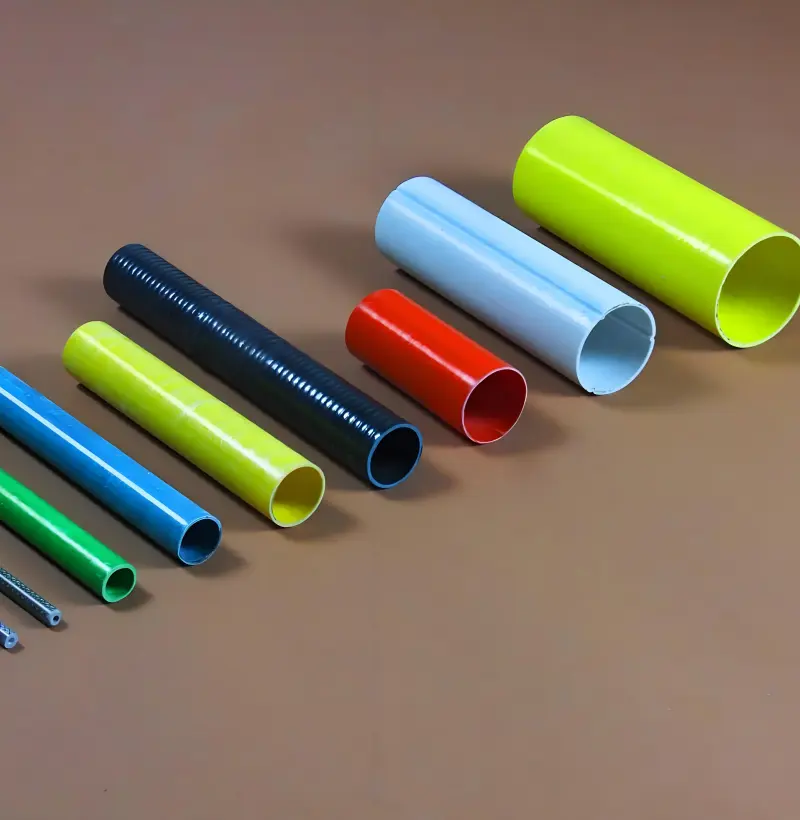

The 3″ and 8″ fiberglass tubes come from the pultruded epoxy fiberglass (FRP) family. But, their different diameters mean they serve different engineering purposes. The 3″ tube (Ø ≈ 89 mm, wall 5–8 mm) is lightweight. It weighs less than a quarter of a similar steel pipe. This makes it easy to carry. It serves as a “flexible artery” for small to medium flow. It’s great for high-pressure pulse applications. These include oil-field sampling, chemical cleaning lines, and vessel ballast systems. The 8″ tube (Ø ≈ 219 mm, wall 10–14 mm) has a ring stiffness of at least 10 kN/m². It works well in large systems like raw-water conveyance, desulfurization, and seawater cooling. This tube can replace DN200 carbon steel or HDPE and cut pumping energy by more than 15%.

Corrosion resistance & hydraulic performance

Both the 3″ fiberglass tube and the 8″ fiberglass tube share core advantages:

Corrosion resistance: The epoxy resin matrix is stable in chemicals with a pH range of 1 to 14. In the same salt-spray test, FRP loses less than 0.1 mm of thickness in 25 years. In contrast, carbon steel can lose about 2 mm during that time.

Lightweight & low friction: Bulk density 1.8–2.0 g/cm³; absolute roughness (k) ≈ 0.0084 mm. Hydraulic head loss for FRP with the same bore is about 60% of that for steel. This lets you downrate one pump class and save energy while it operates.

Suitability by Flow Scale:

3″ FRP is great for high-pressure, pulsating small flows.

8″ FRP works well for cubic meter scale continuous flows and uses less energy.

Mechanical properties & dynamic behavior

Axial tensile strength: Pultruded rovings have an axial tensile strength of at least 320 MPa. This is about 1.4 times stronger than 304 stainless steel.

Elastic modulus: about 25 GPa (≈1/8 of steel). The lower modulus makes FRP more flexible. This helps it respond to foundation settlement or water hammer. As a result, it reduces stress at joints and lowers the risk of leaks.

Non-magnetic & zero eddy-current loss: FRP is non-magnetic. It’s ideal for cable sheaths or conduits in high-voltage substations and metro signaling. It helps avoid eddy-current losses. Plus, there’s no need for grounding or shielding like with metal sheaths.

Temperature range:

Standard epoxy FRP: −40 °C to +120 °C

Vinyl-ester systems: up to approximately 150 °C

This range suits most municipal and industrial needs.

Lifecycle cost & installation advantages

The key benefit is the whole-life cost. FRP doesn’t need cathodic protection, internal rubber lining, or extra epoxy coating. Over 30 years, maintenance costs for pultruded FRP pipes are about 20% of those for carbon steel. Weight savings cut installation labor by about 40%. This often means no need for large cranes. Small crews can work at night. They can backfill right after, which cuts down on traffic disruption.

Typical specifications & substitution potential

Typical specifications & substitution potential

3″ fiberglass tube: OD ≈ 89 mm, wall 5–8 mm — suited for mid/high-pressure pulse lines.

8″ fiberglass tube: OD ≈ 219 mm, wall 10–14 mm, ring stiffness ≥ 10 kN/m² — suited for DN200 replacement in large-flow systems.

Hydraulic Benefit: The friction factor and roughness lower the pumping head by about 40%. We compare this to steel of the same diameter.

Temperature & chemical range: pH 1–14 chemical resistance, −40 °C to 120 °C (vinyl ester to 150 °C).

Procurement & customization

For bulk orders of strong, corrosion-resistant pultruded FRP, contact Hengshui Hongwo. Production capacity: 12,000 t/year pultrusion. You can customize DN25–DN400. Pressure classes range from PN6 to PN25. Lengths of 6 m or 12 m are available. End finishes: plain end, threaded, flange, socket. In-stock items ship within 3 days. Third-party test reports are available (SGS ring stiffness test, Barcol hardness). For drawings, samples, or quotes, please reach out to Hengshui Hongwo. They offer both the 3″ and 8″ fiberglass tubes to meet your needs.

Overview

Overview Typical specifications & substitution potential

Typical specifications & substitution potential