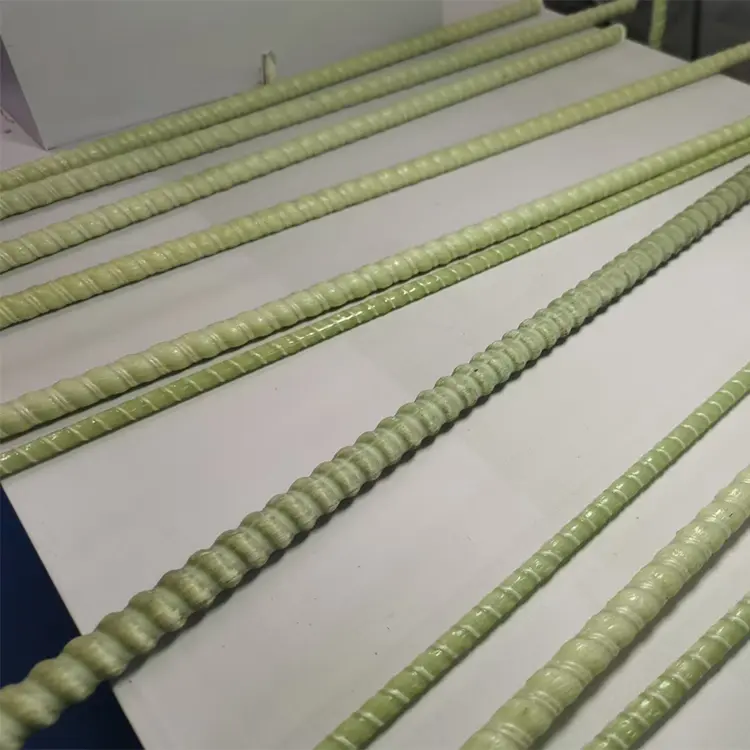

What is Fiberglass Rebar?

Fiberglass rebar, also known as Glass Fiber Reinforced Polymer (GFRP) Rebar, is a composite reinforcement material used in concrete structures. Unlike steel, it does not rust or conduct electricity, making it ideal for environments exposed to moisture, saltwater, or chemicals. With a weight that is only 25% of steel, fiberglass rebar simplifies transportation and installation while maintaining superior tensile strength.

Key Features & Benefits of FRP Rebar

Advantages Over Steel Rebar

Corrosion Resistance – Unaffected by chloride, saltwater, or chemicals.

Lightweight – 4x lighter than steel, easier to transport and handle.

High Tensile Strength – Stronger than steel by weight, ensuring durable reinforcement.

Non-Conductive – Ideal for applications requiring electrical or magnetic neutrality.

Cost-Efficient – Reduced maintenance and longer service life lower lifecycle costs.

Thermal & Chemical Stability – Performs well in aggressive environments.

Product Data & Technical Documents

Download datasheets, chemical resistance charts, test reports and cutting templates.

Technical Specifications

| Parameter | Value (Typical) |

|---|---|

| Material | Glass Fiber + Epoxy Resin |

| Tensile Strength | 1000–1500 MPa |

| Elastic Modulus | 50–60 GPa |

| Density | 1.9–2.1 g/cm³ |

| Thermal Conductivity | Very Low (Non-conductive) |

| Weight vs. Steel | ~25% of Steel Weight |

| Standard Diameters | 6mm, 8mm, 10mm, 12mm, 16mm, 20mm |

| Colors | Natural / Customized |

Applications of FRP Rebar

Fiberglass rebar is widely applied in civil, industrial, and marine construction projects:

Infrastructure & Roads – Highways, bridge decks, retaining walls.

Marine & Coastal – Docks, seawalls, jetties, waterfront structures.

Industrial Plants – Chemical plants, wastewater treatment facilities.

Foundations & Basements – Corrosion-free reinforcement for underground use.

Tunnels & Mines – Non-conductive reinforcement in underground structures.

Residential & Commercial Buildings – Durable reinforcement for concrete slabs, beams, and walls.

Why Choose Our FRP Rebar?

In-house production with strict ISO-certified quality control.

Customizable diameters, lengths, and coatings.

Competitive B2B pricing for bulk orders.

Global shipping with reliable delivery schedules.

Technical support for project-specific requirements.

Frequently Asked Questions (FAQ)

Q1: Is fiberglass rebar stronger than steel?

Fiberglass rebar has a higher tensile strength-to-weight ratio than steel, but its modulus of elasticity is lower. It provides excellent reinforcement in environments where corrosion resistance is critical.

Q2: Can GFRP rebar be cut on-site?

Yes. GFRP rebar can be easily cut with a diamond blade or carbide tool without requiring heavy machinery.

Q3: Is GFRP rebar approved for structural projects?

Yes. Many global infrastructure projects now specify GFRP rebar, and it complies with industry standards such as ACI, ASTM, and CSA.

Q4: What is the lifespan of GRP rebar in concrete?

It can last over 100 years, significantly outperforming steel in corrosive environments.

Q5: Can GRP rebar replace steel in all applications?

While GRP rebar is ideal for most corrosive and lightweight applications, engineers should evaluate load requirements and structural design before full substitution.