Product Overview

4’x8 fiberglass grating (Molded FRP Panel, 1220 × 2440 mm)

Our 4’×8′ molded FRP grating panels are a standardized, easy-to-handle format built for industrial environments where corrosion resistance, low weight and predictable structural performance matter. These panels are available in common mesh patterns (square and rectangular), multiple resin systems and anti-slip finishes to meet pedestrian, equipment and certain vehicular load requirements.

Why Choose a 4’x8′ Panel?

Optimized panel economy — 4’x8′ aligns with typical modular platform frames to minimize cutting and waste on site.

Inventory & lead-time advantage — 4’x8′ is an industry-standard size widely stocked by major suppliers for faster delivery.

Easy handling & transport — single-person or two-person lifts depending on depth, reducing installation labor.

Spec-friendly — available in HLC (High-Load Capacity) molded variants when wheel or forklift loads are required.

Applications

Industrial platforms & mezzanines

Chemical and wastewater treatment walkways (corrosion environments)

Marine docks and offshore gangways (saltwater service)

Maintenance pits and equipment access platforms

Loading platforms and areas expecting pallet-truck traffic (select HLC styles)

Product Details

Standard 4’x8′ Panel Specifications

All dimensions below are standard industry values for 4’x8 fiberglass gratings in 4’×8′ panels. Verify final selection and allowable spans using manufacturer load tables for the chosen mesh and resin.

| Property | Typical Value (4′ × 8′ panels only) | Notes / Source |

|---|---|---|

| Panel size (nominal) | 48″ × 96″ (1220 × 2440 mm) | Standard molded FRP panel size. |

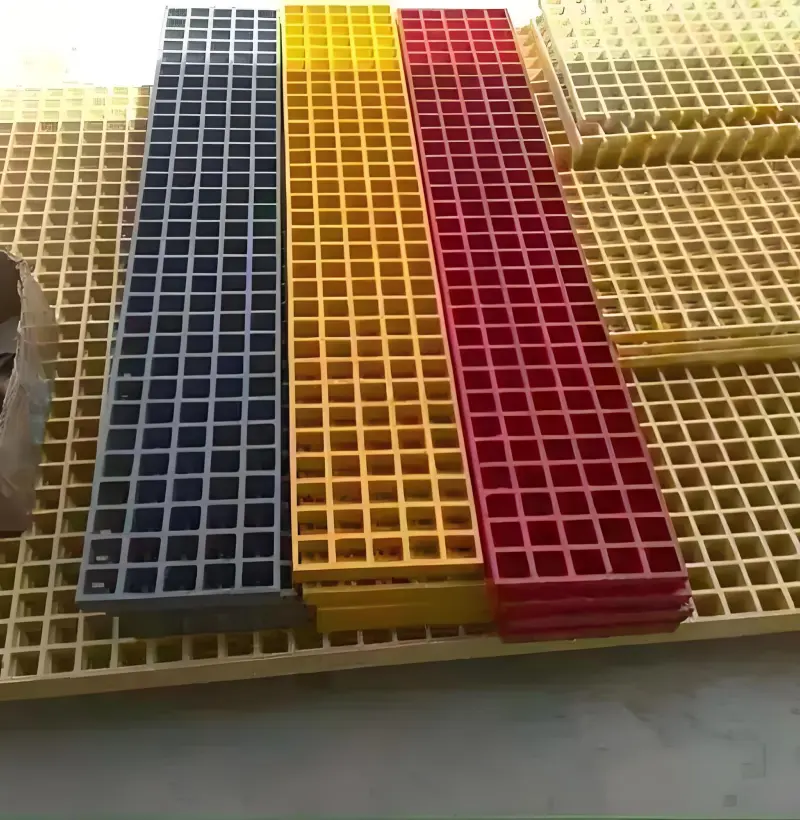

| Available depths | 1.0″ (25 mm); 1.5″ (38 mm); 2.0″ (51 mm) | Most suppliers stock these depths for 4’x8′ molded panels. |

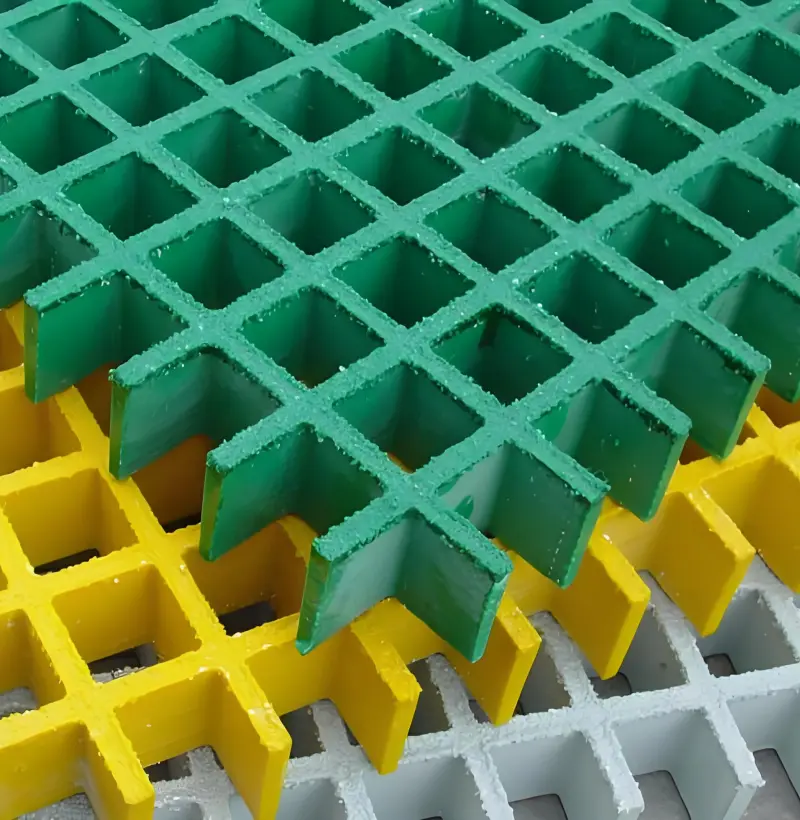

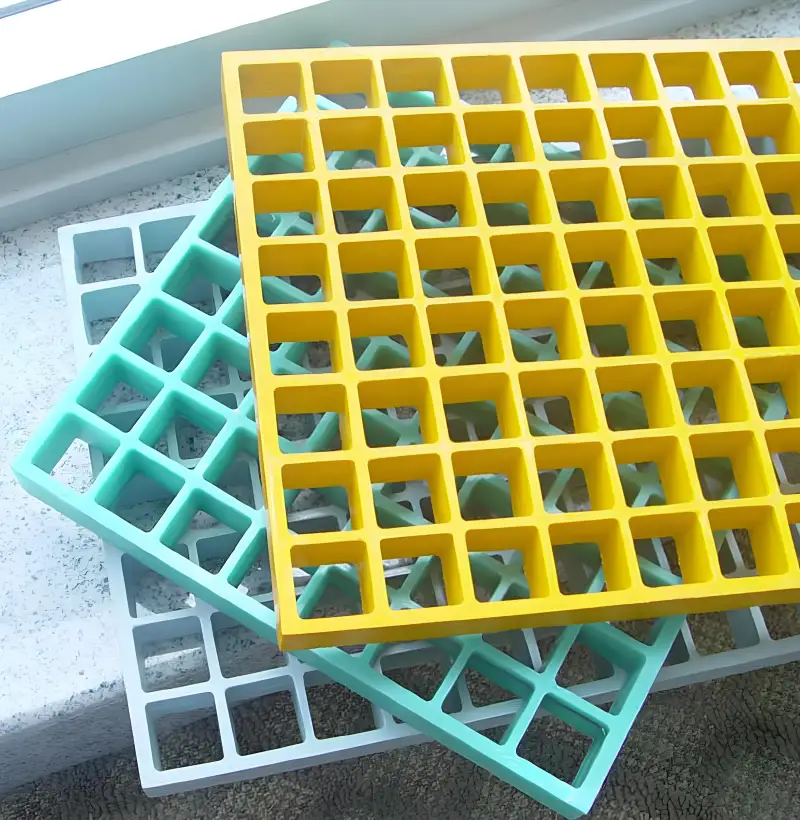

| Common mesh patterns | 1″×4″ rect.; 1.5″×1.5″ sq.; 2″×2″ sq.; other proprietary meshes | Mesh affects open area and load capacity. |

| Typical open area | ~48% – 72% (depends on mesh) | HLC styles trend toward lower open area (~48%); standard molded square meshes often 68–72%. |

| Approx. weight (per panel) | ~25–135 lb (11–61 kg) depending on depth & mesh (see note) | Example: 4’x8′ 1.5″ square-mesh panels ≈ 2.5–4.1 lb/ft² → panel weight ≈ 80–131 lb. Verify per style. |

| Surface options | Smooth meniscus, integrally gritted (Aluminum Oxide), concave | Grit surfaces increase COF for wet/oily areas. |

| Resin systems | Polyester, vinyl ester, Corvex®, Vi-Corr® (manufacturer brands) | Resin choice determines chemical & temperature resistance. |

| Typical temp range | −40 °C to +150 °C (depends on resin) | Verify with manufacturer for high-temp service. |

| Load data | See manufacturer molded/HLC load tables (span & mesh dependent) | Use official load tables for allowable spans & point/ uniform loads. |

Design note: open area, mesh and resin selection significantly affect panel weight and allowable spans — always reference the supplier’s molded load tables for the chosen 4’×8′ style.

HLC (High-Load Capacity) 4’x8′ Options

For sites that require pallet-jack or limited forklift traffic, HLC molded 4’x8′ panels exist (HLC often available in 1.5″ and 2″ depths with a rectangular 1″×2″ load-bar geometry and ~48% open area). These are supplied with optional bonded/closed edges and heavier load-bar geometry to improve wheel performance. Always verify wheel load and wheel width against the HLC load chart.

Advantages

Corrosion resistance — outlasts uncoated steel in aggressive chemistries, reducing replacement cycles.

Low maintenance — no painting or anti-corrosion coatings required.

Lightweight — lower dead load reduces supporting steel and installation labor.

Slip-resistance — integrally gritted top available for safety-critical walkways.

Standardized 4’x8′ sizing — simplifies quoting, on-site layout and replacement parts.

Comparison Table (4’x8′ FRP vs alternatives)

| Decision Factor | 4’x8 fiberglass grating (this page) | Steel Grating (48″×96″ panels) | Aluminum Grating |

|---|---|---|---|

| Corrosion resistance | Excellent — molded resin systems resist acids, salts, H₂S. | Poor without coating — frequent maintenance in corrosive sites. | Good, but galvanic concerns and higher cost in marine salt spray. |

| Weight | Light — lowers structural cost and simplifies handling. | Heavy — higher support & installation cost. | Lighter than steel; heavier than some FRP styles. |

| Standard panel availability | 4’x8′ widely stocked — predictable lead times. | Widely available. | Widely available. |

| Vehicular / Forklift service | Available in HLC 4’x8′ variants — check load tables. | Standard for vehicles. | Can be used depending on design. |

| Life-cycle cost | Often lower in corrosive settings due to minimal upkeep. | Often higher due to corrosion maintenance. | Moderate. |

Installation & Procurement Guidance

Specify panel orientation: orient load bars across the shorter span where wheel traffic is expected. Provide wheel width, wheel load and clear span when requesting HLC guidance.

Edge treatment for forklifts: request bonded/closed perimeter or install steel toe plates where forklifts cross joints.

Cutting & field modification: 4’x8′ panels are field-cuttable with fiberglass cutting tools; finish edges per manufacturer recommendations.

Request load tables: the supplier’s molded/HLC load tables are the definitive source for allowable spans and concentrated loads — include them in submittal.

FAQ

Q1 — Can a 4’x8 molded FRP panel support forklifts?

A: Only certain HLC 4’x8′ molded panels are engineered for forklift wheel loads. Provide wheel load, wheel width and span so the supplier can select the correct HLC style and reference the manufacturer’s 4’x8′ HLC load table.

Q2 — What depth should I choose for a 4’x8′ platform?

A: Typical choices are 1″ (pedestrian), 1.5″ (heavy pedestrian/ light equipment) and 2″ (heavier equipment / larger spans). Use the load table for allowable spans at each depth for your application.

Q3 — How heavy is a 4’x8 FRP panel?

A: Weight depends on depth and mesh: example ranges are ~25 lb (1″ thin, airy mesh) up to ~130 lb (dense 2″ HLC-like panels) per 4’x8′ panel. Always request the supplier’s panel weight from their spec sheet for the chosen mesh/resin.

Q4 — Do you offer cut-to-size or bonded edge panels from 4’x8′ stock?

A: Yes — many manufacturers supply cut-to-size panels from 4’x8′ stock and bonded/closed-perimeter options for vehicular crossings. Specify finish and edge details at quote.

Q5 — Are 4’x8 molded panels available in fire-retardant resins?

A: Yes — select resin systems and formulations offer improved flame performance; request the resin/fire-spec and ASTM/UL test reports during procurement.