Key Features of Pultruded Fiberglass Grating

High Strength: The pultrusion process enhances the material’s mechanical properties, offering a high load-bearing capacity.

Corrosion Resistant: Ideal for use in environments exposed to chemicals, water, and extreme weather conditions, pultruded fiberglass grating does not rust or corrode.

Slip-Resistant: The textured surface provides superior slip resistance, making it suitable for wet or oily areas.

Lightweight: Pultruded FRP grating is significantly lighter than metal alternatives, reducing installation costs and effort.

Fire-Rated: Meets fire resistance standards, ensuring safety in case of fire hazards.

Low Maintenance: The durable nature of fiberglass minimizes the need for frequent maintenance or replacements.

Applications of Pultruded FRP Grating

Applications of Pultruded FRP Grating

Chemical Processing Plants: Resistant to the harsh chemicals commonly found in chemical manufacturing processes.

Wastewater Treatment Facilities: Ideal for use in environments with high moisture and exposure to corrosive substances.

Food and Beverage Industry: Easy to clean and maintain, pultruded fiberglass grating is perfect for food production areas.

Offshore Platforms: Withstands exposure to saltwater, making it an excellent choice for marine environments.

Power Plants & Refineries: Ideal for use in areas with high foot traffic and heavy machinery, offering long-lasting performance.

Specifications of Pultruded FRP Grating

| Specification | Details |

|---|---|

| Material | Fiberglass Reinforced Plastic (FRP) |

| Manufacturing Process | Pultrusion |

| Surface Type | Smooth, Gritted, or Serrated |

| Standard Size | 1220mm x 3660mm (Custom sizes available) |

| Thickness Options | 25mm, 38mm, 50mm |

| Load Capacity | Up to 10 kN/m² |

| Fire Rating | Class 1 (ASTM E-84) |

| UV Resistance | High (No degradation in sunlight) |

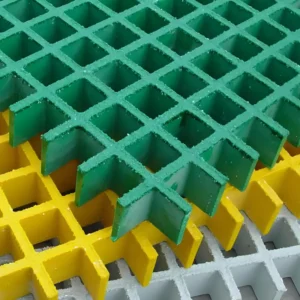

| Color Options | Yellow, Grey, Black (Custom colors available) |

| Weight | Approx. 5-7 kg/m² |

Product Data & Technical Documents

Download datasheets, chemical resistance charts, test reports and cutting templates.

Common Sizes and Dimensions

Standard Panel Size: 1220mm x 3660mm (custom sizes available on request)

Thickness Options: 25mm, 38mm, 50mm

Weight: 5-7 kg/m² depending on thickness

Load Capacity: Rated for loads up to 10 kN/m²

Benefits of Pultruded GRP Grating

Corrosion Resistance: Pultruded GRP grating will not corrode like steel or aluminum, making it ideal for use in chemically aggressive environments.

Slip Resistance: The gritted or serrated surface prevents slipping, which is especially beneficial in wet, oily, or high-traffic areas.

Lightweight Construction: Easier to handle and install compared to metal grating, leading to reduced labor costs.

Low Maintenance Costs: The fiberglass composition of pultruded grating requires minimal upkeep compared to traditional materials.

Fire Safety: Meets stringent fire resistance standards, making it safe for use in hazardous environments.

Customization Options: Available in various colors, sizes, and thicknesses to suit specific project requirements.

Pultruded FRP Grating vs. Other Materials

| Material | Pultruded FRP Grating | Steel Grating | Aluminum Grating |

|---|---|---|---|

| Weight | Lightweight | Heavy | Moderate |

| Corrosion Resistance | Excellent | Poor | Moderate |

| Slip Resistance | High (Gritted or Serrated) | Low (Coated options available) | Moderate |

| Fire Resistance | Class 1 | Class 2 | Class 2 |

| Maintenance Needs | Low | High (Rust and Coating Loss) | Moderate |

| Cost | Cost-Effective | Expensive | Moderate |

FAQ

Q1: What is pultruded fiberglass grating?

A1: Pultruded fiberglass grating is a high-strength, corrosion-resistant material made by pulling continuous strands of fiberglass through a resin. It is ideal for use in demanding industrial environments.

Q2: How is pultruded GRP grating different from traditional metal grating?

A2: Unlike metal grating, pultruded fiberglass grating does not rust, is much lighter, and offers superior slip resistance, making it more durable and low-maintenance.

Q3: Can pultruded FRP grating be customized to fit specific project needs?

A3: Yes, we offer custom sizes, colors, and thicknesses to meet the exact requirements of your project.

Q4: Is grating suitable for outdoor use?

A4: Yes, pultruded GRP grating is UV-resistant and can withstand outdoor conditions, including exposure to sunlight and extreme weather.

Q5: How do I install grating?

A5: Installation is easy and can be done using simple bolting or clamping methods, reducing the overall labor and installation costs.

Applications of Pultruded FRP Grating

Applications of Pultruded FRP Grating